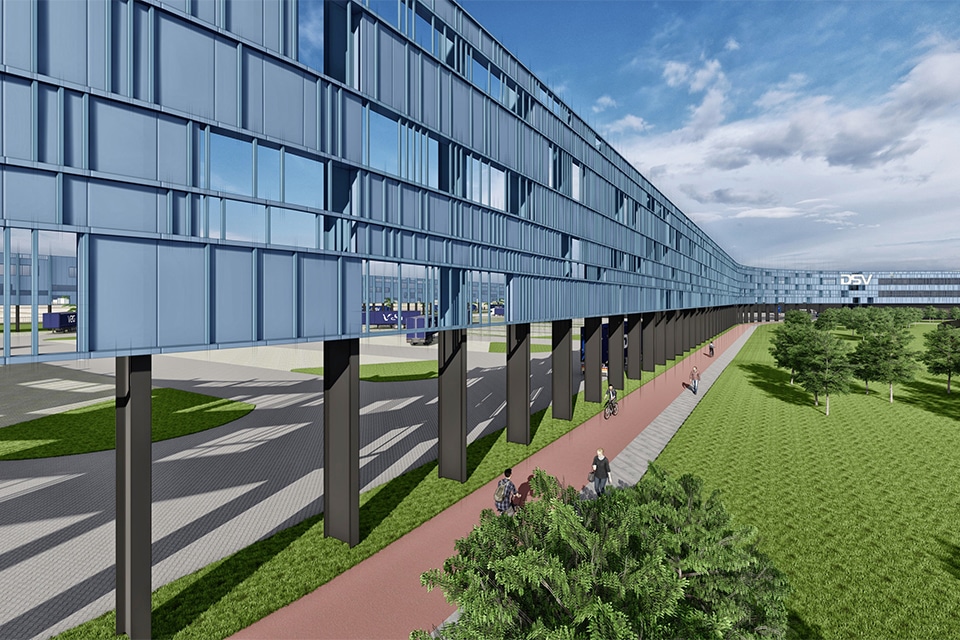

9,700 m2 distribution center expansion

Solar Nederland's distribution center in Alkmaar was expanded by 9,700 m2 in eight months, spread over the ground and first floors. Main contractor De Geus Bouw realized this project in cooperation with Elektropartners, Duteco and other regular partners. The new part of the distribution center was completed in late 2023. "Through tight planning and a lot of consultation, we were able to realize the project in a short period of time," says De Geus.

Solar Group is a leading European sourcing and service company, primarily in the fields of heating and plumbing, ventilation and climate and energy solutions. The expansion in Alkmaar is part of the company's large-scale international project, which ensures a highly efficient supply chain. Project leader Joris Meijer of De Geus Bouw: "By consulting a lot with all parties involved from the beginning and planning tightly, we were able to realize this project in a short time. We also made sure that we had all the necessary materials in stock on time. As a result, construction went smoothly." After installing the piles and making the foundation, the steel structure was installed. This was then fitted with facade cladding and roof panels with roofing. Finally, the concrete floor was poured inside and a sprinkler system was installed. On the roof came 1,260 solar panels to provide the building with the electricity it needs.

With the expansion, Solar Netherlands increased its warehouse capacity to 35,000 m2. The mezzanine floor was increased by 2,000 m2 and additional office spaces were added. The automated storage and order picking system could be expanded to 65,000 totes.

Furnishing the outdoor area

In addition to the construction of the distribution center, De Geus Bouw also provided 13,400 m2 of outdoor area for the storage of materials. "We installed sewerage and drainage and provided the site with granular pavement and paving. Finally, we installed a fence around the site."

High flatness class

A special detail about this project is that the floor floors were realized in a very high flatness class. An autostore was realized on the upper floor with self-propelled robotic cars that take care of the internal logistics of the stock of small items. To prevent these from falling into failure, it was necessary to level the floors perfectly.

Construction Team

Meijer is satisfied with the course of the project and the cooperation with the other parties. "Even before we received the contract, we switched with several regular partners, such as Kuipers Funderingstechniek for the piling, Cazant for the concrete work, BRB Staalbouw for the steel construction and cladding, West Friesland Dakbedekkingen for the roofing, Elektropartners for the electrical installation and Duteco installatietechniek for the air treatment and plumbing installation. We took on the project as a construction team. We know each other's working methods and because of the long-term cooperation we also dare to be critical of each other."