Giga-Screed makes concrete floors ultra-flat

Super flat floors

To get the most out of distribution centers, clients are setting the bar higher and higher. They want the largest possible spans, combined with ultra-flat concrete floors. After all, the larger the free space, the more efficient they can design the centers. This is where the Giga-Screed offers the solution.

Ultra-flat floors are an essential component of ever-expanding distribution centers. With racks getting higher and higher, even minimal height differences can get in the way of efficient use. Automatic storage and picking systems demand ever-increasing levels of perfection.

Unique length

At 27 meters long, the Giga-Screed is the only one of its kind. The largest screed to date spans some 23 meters. "That's already a considerable length," thinks Dirk Loos, director of the Loos Concrete Group. "But with DC owners wanting to use the work floors more and more effectively, we decided to build the screed even larger."

Self-supporting

When developing the Giga-Screed, Loos Betonvloeren immediately implemented some innovations. For example, the Giga-Screed is self-supporting; it does its work - after assembly - without the support of a forklift or crane. To this end, the drive units are equipped on both sides with extendable legs with driven, steerable wheels. With this equipment, the Giga-Screed can level 2,000 to 3,000 m² of floor area per day. The unit is controlled with a wireless remote control.

Super flat

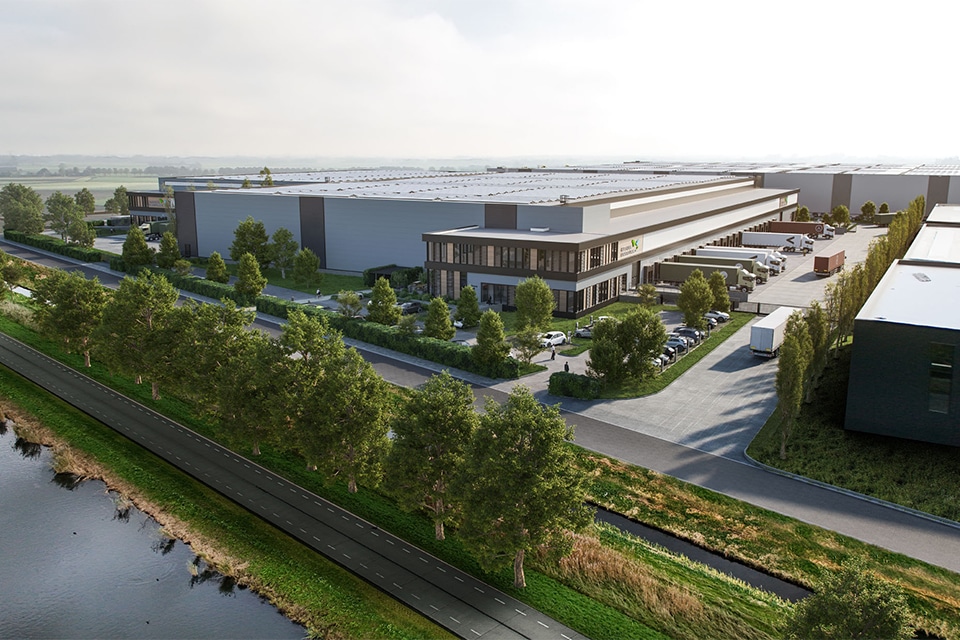

The Giga-Screed has now made its debut. It happened in Den Hoorn in South Holland, where the German company Goldbeck is building a distribution center of some 60,000 m². Part of the floor had to be super-flat, in accordance with NEN 2747 Class I. "The floor was 18 cm thick and reinforced with a top mesh and steel fibers," Loos explains. "We used the Giga-Screed here and it met the specified requirements without any problem."

Loos Concrete Flooring

Tour 8

1713 GP Obdam

T +31 226 45 30 25

E info@loosbetonfloors

W www.loosbetonvloeren.nl