Sustainable installation techniques for Bleizo Logistics Centre

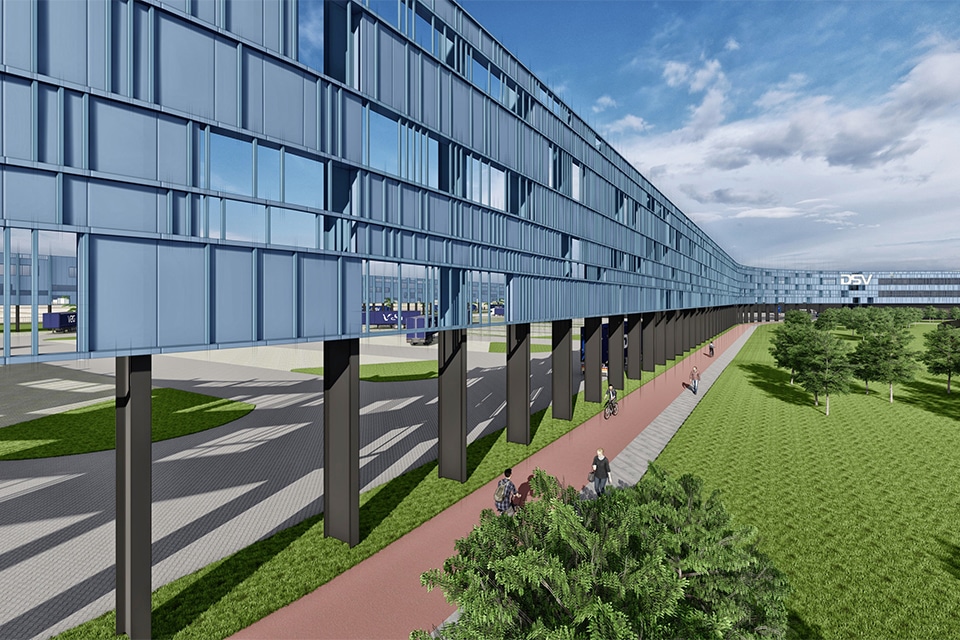

The DC will include approximately 43,000 m² of warehouse, 2,700 m² of office space and 3,700 m² of mezzanine, as well as 50 loading docks and approximately 300 parking spaces. The project will be realized according to the BREEAM-NL 'Very Good' quality and sustainability requirements. The installations of Barth Installatietechniek, part of the Barth Group, make an important contribution to this.

Subcontracted by Cordeel Nederland, Barth Installatietechniek is realizing all electrical, mechanical and sanitary installations in the Bleizo Logistics Centre. "After intensive preparation, the execution started in mid-November," says project manager Erik Lugtenburg. "For heat generation, we are installing two air/water heat pumps on the roof of the new building. Water-fired air heaters were chosen as the delivery system in both warehouse parts (A and B), while the office areas will be equipped with underfloor heating. By combining the radiant heat from the floor with the speed of air heating (VRF system), optimum comfort and minimum energy consumption are guaranteed. The two offices will each have their own air handling unit, to which a heat pump will also be connected."

There will be 148 solar panels on the roof of the new building. Barth Installatietechniek is also installing 20 charging stations. "For the lighting, LED light lines have been chosen in the halls and LED recessed spotlights and inset fixtures in the offices," said Lugtenburg. "The fixtures on the window side will be equipped with daylight controls, which will allow for considerable energy savings." All toilet groups will have their own shut-off valve in the water system, which will be connected to the lighting system. This eliminates water wastage due to leaking faucets or flushing toilets.

Project info

Load-bearing floors in former polder area

The new Bleizo distribution center in Bleiswijk is being built on a greenfield site in a former polder area; an all but load-bearing subsoil. Reason enough for main contractor Cordeel to outsource the complete 'care' of the industrial floors and foundations to Twintec.

"The good (read: load-bearing) building sites in our country are pretty full," begins Jeroen Boers, Production Manager at Twintec. "Increasingly, so-called greenfield sites, or former pastures with predominantly clay and peat soils, are being diverted, especially above the major rivers. So too for the new Bleizo distribution center in Bleiswijk. The challenge for us was therefore not so much in achieving the correct flatness, but in realizing sufficient bearing capacity, even in a 'wet' period (autumn). We therefore took care of the complete process, from engineering and foundation to the realization of the Twintec Ultimate hybrid floors."

Both the pile plan and the floor are tailored to the limited bearing capacity of the ground, Boers continued. "We started piling immediately after the summer break in 2020 and will deliver just before Christmas 2020. Then we will have installed a total of 11,500 HiSpeed VSD piles in lengths ranging from 15 to 18 meters. In January we will start the floors, a total of 42,000 m², which we expect to deliver by mid-February. It is truly a project under high voltage. Literally and figuratively."

Project info

1,850 tons of steel

The new Bleizo Logistics Centre has a steel backbone. Commissioned by Cordeel, Hanse Staalbouw is designing, producing and realizing the complete steel structure. No less than 1,850 tons of steel are involved.

"We started detailed engineering in week 14 of this year and began production of the steel structure just before the summer break," says Tim Hoek of Hanse Staalbouw. "By producing 'ahead' in a structured way, we ensure that the assembly does not stagnate. In fact, the entire structure will be assembled by us in a time frame of only 12 weeks and will be delivered in early 2021."

Since the founding of the "Hanse company" in 1907, Hanse Steel Construction has grown into a recognized steel construction company and a household name in the construction world. "We specialize in the steel construction of complete commercial buildings in the agricultural, industrial and utility sectors."