Working more efficiently through smart warehouse design

SUSTAINABLE DISTRIBUTION CENTER FOR SHIPBUILDER

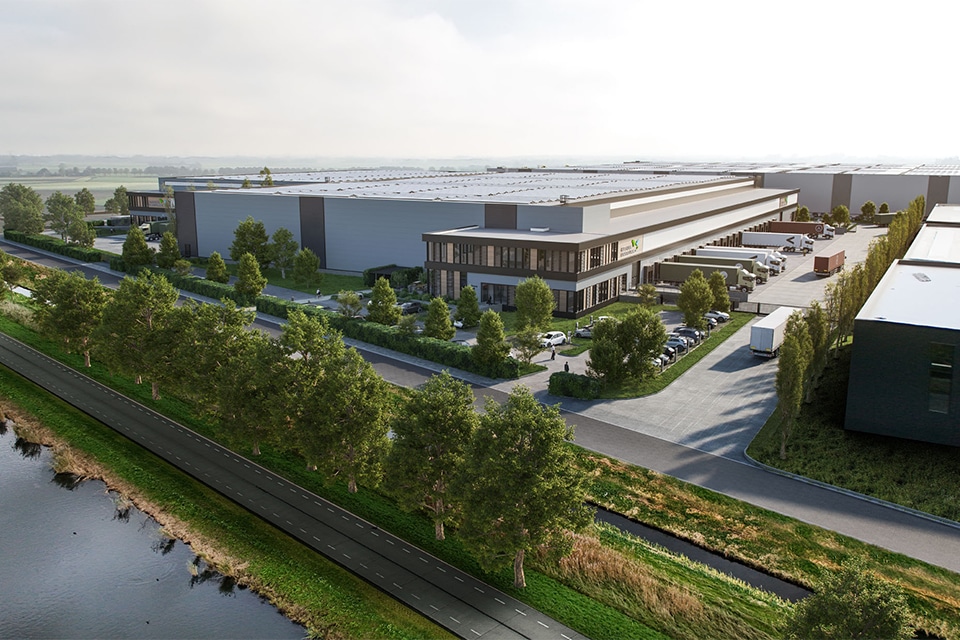

BMN De Klerk built an energy-efficient distribution center in Schelluinen for Damen Shipyards Group with a storage area of some 14,500 m2 and 800 m2 of office space. The building is now in use. "The cooperation with all parties has been constructive and solution-oriented."

The building will receive a BREEAM "Very Good" certification. It is completely gasless, has an A++++ energy label, is equipped with solar panels and the lighting works with motion sensors. The project was realized in cooperation with owner Deltabrug Beheer from Hardinxveld-Giessendam and Van Es Architecten from Sliedrecht. Martijn van Tilborg, logistics manager of Damen Shipyards, explains why it was time for a new distribution center: "There are two reasons for this: our rental contract expired and Damen is very committed to sustainability. Not only for the ships we produce, we are working on a total energy transition. For example, we are electrifying the ships, but we also want to make our real estate more sustainable. Deltabrug gave us the opportunity to include our wishes during construction. This did sometimes present challenges for BMN De Klerk when things had to be changed, but this was handled very well."

Peter Huizer is one of the directors of general contractor BMN De Klerk. He says he was around the table at an early stage to help think about the project. "It was the first time for us to build such a large building with BREEAM label 'Very Good'. In addition, the construction time was very short, about ten months. We are proud that we succeeded."

More storage in less square footage

The distribution center is eleven meters high and set up to be as efficient as possible. For example, the floor supports many more pounds than in the old building, allowing for larger racks. In less square footage, 25% more can be stored. Damen Shipyards employees need to travel fewer meters to check and ship goods. Calculator/work planner Gerard van der Kuijl of BMN De Klerk: "There are some 3,000 piles under the entire distribution center and the outdoor area. This was necessary because otherwise the underlying ground would subside. The building also consists of a steel structure, facade panels and a steel roof and is equipped with loading docks." To achieve the 'Very Good' BREEAM certification, a full dossier of the project was created. Just think of trip records, delivery notes, measuring the CO2 emissions and testing the airtightness of the building.

As in any project, there were challenges. Consider, for example, the poor subsoil, but also the many pipes that had to go into the building. Huizer: "We had to build from the inside because of the limited space. The installation height was also limited. But through constructive cooperation with each other and compromise, we managed to get everything done. We worked with regular suppliers on this, so we could switch quickly. Cooperation with the municipality of Molenlanden, the water board and the fire department was also constructive and solution-oriented."