The hidden power behind the natural stone facade

Prefabricated rear structure for The BaanTower

LomaxSystems specializes in the development and production of facade solutions for ventilated facades. “We develop aluminum back constructions for virtually all facade materials,” says Erik Pijnenborg, Sales Manager at LomaxSystems. “From aluminum to ceramic, natural stone, BIPV panels, concrete, glass, wood and terracotta. The beating heart of our company is our engineering department, which works together with the customer to create project-specific façade solutions that can be assembled efficiently, reliably, safely and quickly. The BaanTower in Rotterdam is a great calling card for this.”

Project The BaanTower came up for LomaxSystems through regular customer Kolen. “The design already included a rear construction for mounting the natural stone cladding, but Kolen asked us to help think about a more efficient alternative,” Pijnenborg says. “Our team of specialists took stock of the project request and project conditions and translated them into a unique façade solution that could be assembled efficiently, reliably, safely and quickly.”

One floor per week

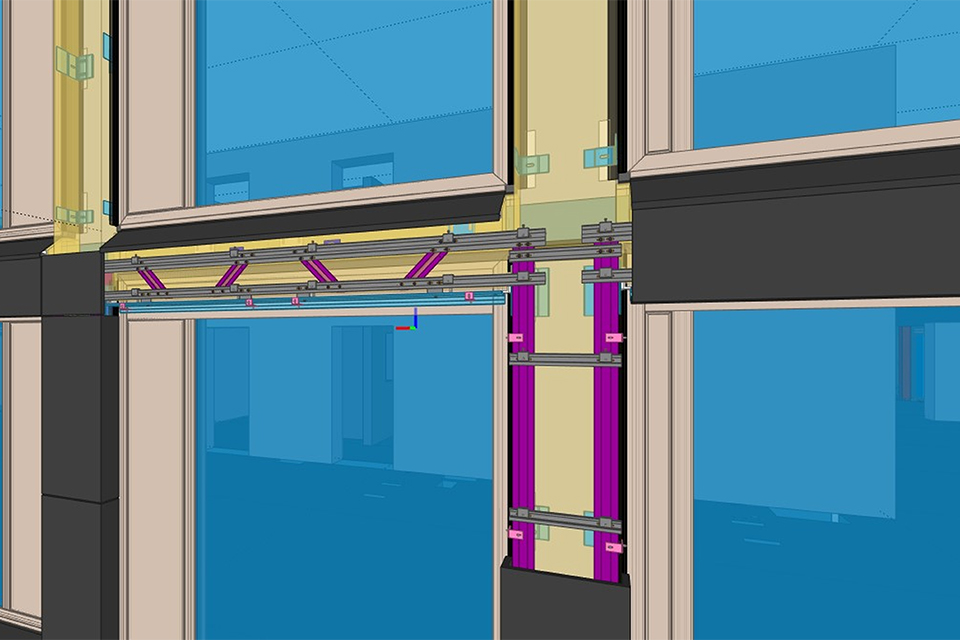

“The result is a prefabricated system, delivered to the project just-in-time per floor, fully dimensioned, clearly numbered and equipped with the correct drill holes,” Pijnenborg said. “This allows our client to assemble, set and attach the complete rear construction in a lightning-fast one-story-per-week pace, as well as the natural stone cladding.”

Custom solution

At the base of the precast system are aluminum extrusion profiles that were specially engineered and extruded for The BaanTower, says Pijnenborg. “Thanks to our construction, the facade builder can easily attach his natural stone facade by means of a hook-and-loop system. In order to guarantee the reliable fastening of the heavy facade elements also in the long term, we support Kolen with all relevant strength calculations. In addition, we created and coordinated the assembly drawings with the facade builder and support the assembly.”

Comprehensive assembly guidance

“At the start of the project, our on-site specialists checked with us for the correct attachment points,” Pijnenborg says. “In addition, they checked that construction and engineering correspond exactly. After all, the second floor is normative for all floors above it. Thanks to this approach, we can make timely adjustments if necessary, again resulting in an efficient, reliable, safe and fast assembly.” The last prefabricated façade solutions in Rotterdam will be delivered in early 2026.