Perfect connection of concrete and steel

A perfect fit between (precast) concrete and steel hinges on careful engineering. In the realization of DSV's new cross-divisional campus, this important task lay with ADS-Ertner B.V.

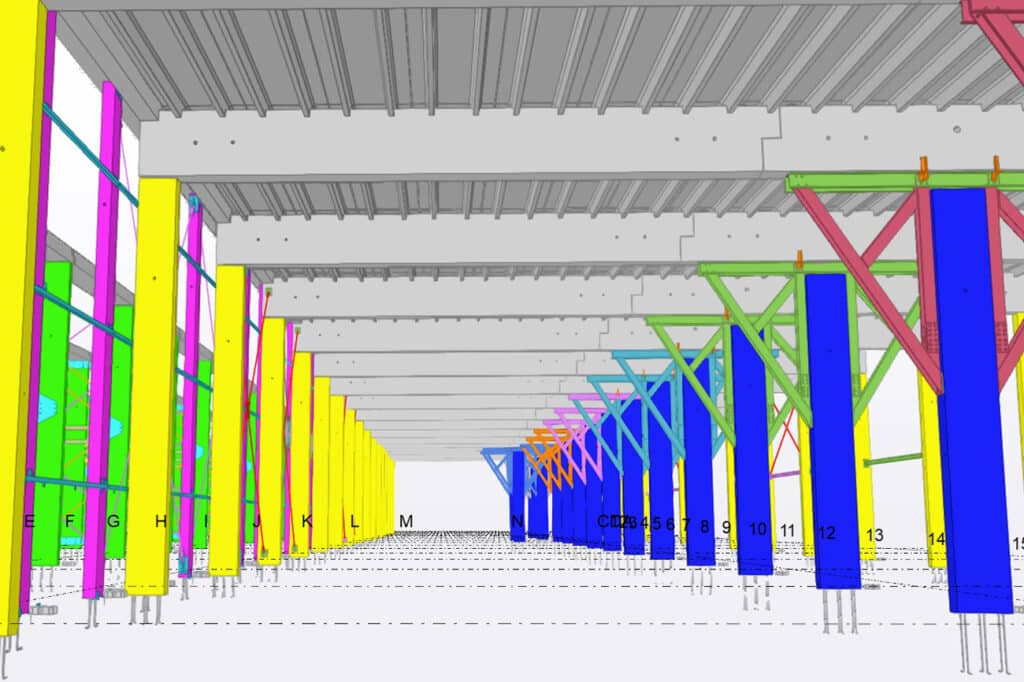

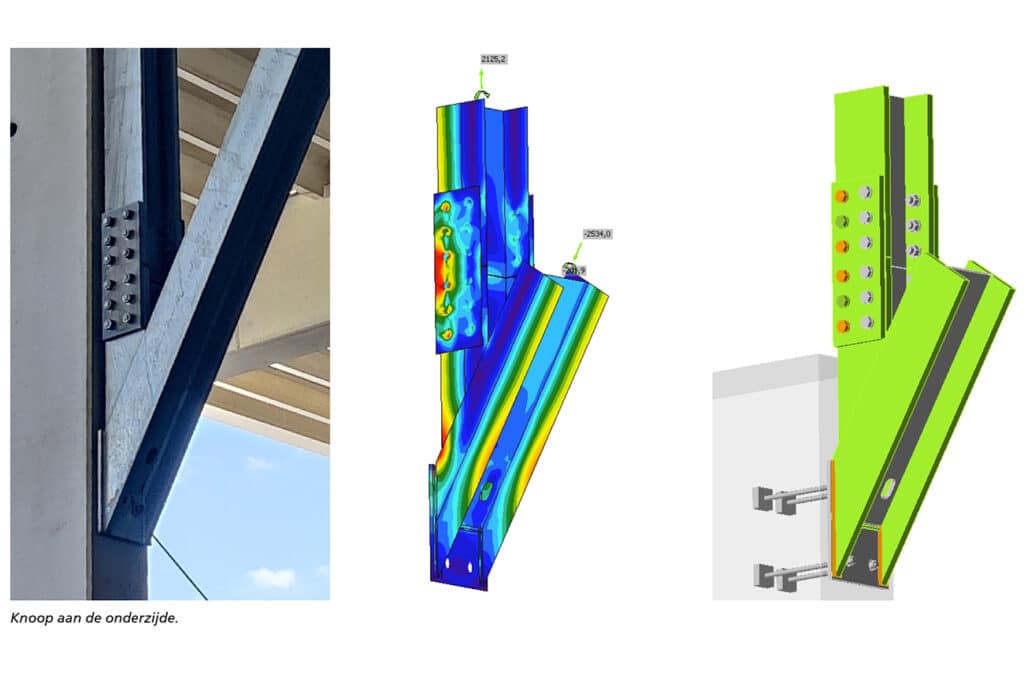

The experienced engineers and draftsmen of ADS-Ertner B.V. carry out all possible technical calculations and drawings on a daily basis for customers in electrical and installation engineering, steel and equipment construction and architecture. The independent drawing and engineering company has a very loyal customer base, which also includes steel supplier Reijrink Staalconstructie b.v. and precast concrete producer Holcon BV. "For DSV's project in Venlo, both Reijrink Staalconstructie b.v. and Holcon BV put us forward to contractor Unibouw BV," says Arco de Gelder, consultant, project leader and structural engineer at ADS-Ertner B.V. "For example, to work out the steel stability systems (wind bracing and yokes) and connections (welds and bolts) between the precast concrete elements of the warehouse and shipping deck. We provided all the detailed calculations for the steel connections. Moreover, we worked out the specific details at a very early stage and together with engineering firm Lincon BV. Hand in hand with all relevant stakeholders, which enabled much more efficient and constructively favorable engineering, production and construction." Following the engineering, ADS-Ertner B.V. also provided all overview and workshop drawings.

Early to the table

In the lead structural engineer's initial design, precast concrete construction and steel construction were completely disconnected, De Gelder says. "Because we were at the table very early on, we were still able to integrate these systems. This allowed the construction to be considerably lighter. A major challenge here was to prepare everything well and to have the chief structural engineer properly calculate all the design optimizations. But also to continuously streamline two different disciplines. Both in the design phase, and during the mutations in the execution phase."

Strong piece of engineering

Proportionally, very many Willems Anchors have been applied, De Gelder says. "A total of 440 are involved. Another special feature is the steel yoke under the shipping deck, measuring as much as 9 by 6 meters. This yoke was attached to the concrete columns, after which the concrete beams were lifted on top. We helped ensure that the loads were added in exactly the right places. But also that play is secured in the right places. A strong piece of engineering of which we are extremely proud."

Whereas the main structural engineer had initially designed a structure with tubes, ADS-Ertner B.V. worked out various profile optimizations. Thanks in part to these efforts, DSV benefits from an optimal construction, which requires less material, less assembly time and fewer modifications. In this way, ADS-Ertner B.V. is also making an important contribution to the sustainability ambition in this project.