Thoughtful combination of concrete, steel and wood

Stabiel Management has engineered, delivered and assembled the prefabricated shell for the new Culture, Education and Media Building (COM Building) in Ridderkerk. A nice mix of materials was chosen here, says technical consultant/project manager Henri van Nistelrooy. "Thanks to a well-considered combination of precast concrete walls, steel columns and beams and wooden columns and beams, a high-quality hybrid shell has been created, in which each building material does exactly what it is intended for."

The new COM building houses a green campus, a cultural center, sports facilities and the expansion of Gemini College and was designed by DP6 architecture studio. Jongekrijg Maasbouw, part of Bouwgroep Schrijver, is responsible for construction. On behalf of this contractor, Stable Management designed a number of optimizations and clever details, resulting in an optimal hybrid design as well as faster assembly time. "Initially, this project prescribed in-situ concrete walls," Van Nistelrooy says. "Partly on our advice, this was deviated from. A number of visible concrete walls had to be provided with a wood motif, which was difficult to achieve in situ. Therefore, the prefab concrete plant was diverted. Here, special textured formwork mats were incorporated into the molds, revealing a beautiful wood grain pattern. In this project, functionality and aesthetics come together nicely."

Hybrid construction

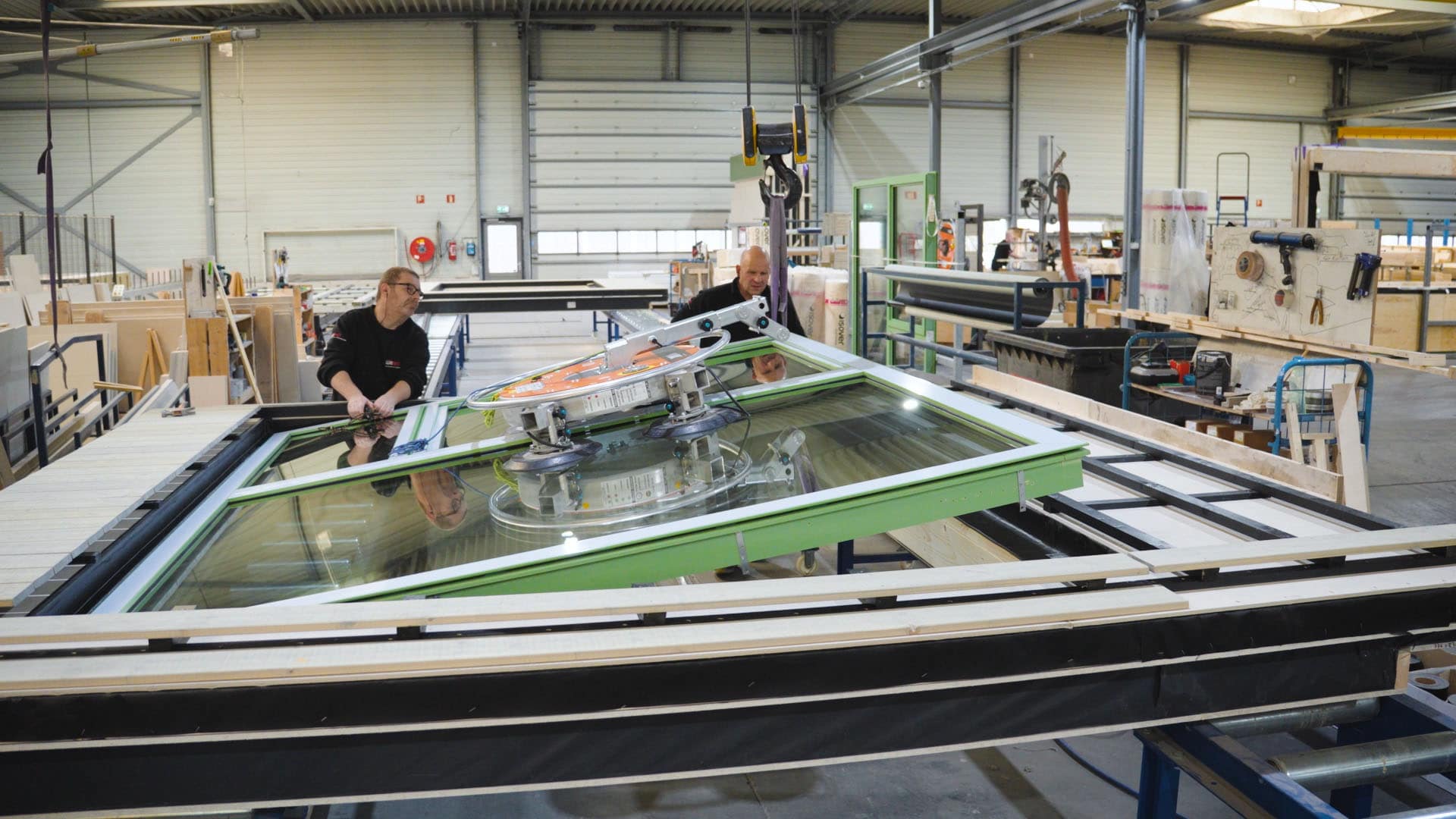

Thanks to hybrid construction, each material excels in its function, Van Nistelrooy emphasizes. "The strength of each product is used to the maximum." As an example, he mentions the concrete walls, but also the wooden columns and beams at the viewing workstations and steel columns and beams at the overhangs, large doors and piping routes. "Wherever possible, wooden columns were implemented over two floors. Moreover, by extending the concrete walls, the wooden columns could be dropped in a number of positions. Two awkward stability portals with wooden columns and steel wind crosses were replaced with precast concrete, and the steel connections were factory pre-assembled to the wooden columns on our advice."

4,300 m2 in seven weeks

The different types of prefabricated components were assembled entirely in-house and by one multifunctional assembly crew, Van Nistelrooy says. "In just seven weeks, we erected a 4,300-square-meter building." By mid-May, the construction was complete. The new COM building is expected to be occupied by the end of this year.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Stable Management.

Contact opnemen

Contact opnemen