Lifting shed offers optimum in safety, quality and lead time

Contractor company Civil techniques deBoer bv has been active and innovative in civil construction and jacking techniques for more than 40 years. "We are constantly pushing the boundaries of what is technically possible," says director Anton van Vliet. "After all, ever heavier, higher and larger structures have to be built in ever fewer square meters. The innovative modular lifting shed, which we engineered and deployed during the construction of De Zalmhaven I, is a sophisticated example of this."

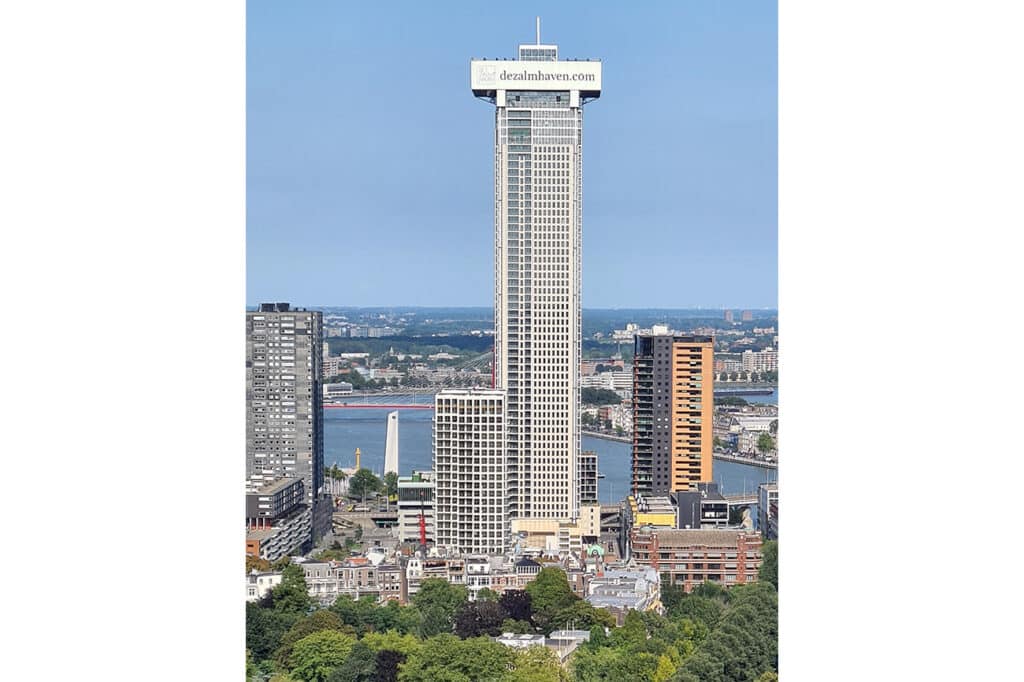

At 59 stories and 215 meters tall, Zalmhaven I is not only the tallest residential tower in the Netherlands, but also the tallest in the world in precast concrete. Because of the inner-city location, tight construction site and short lead time, not only were prefab elements chosen, but also construction with a hoist shed. In this way, the contractor BAM Bouw & Techniek and Civiele technieken deBoer bv also provided increased safety for construction site workers and the environment.

Optimum in scale, scope and functionality

"The hoist shed is a construction method that has been around for some time," Van Vliet emphasizes. "For example, back in 2011 we engineered, built and applied a hoisting shed for the expansion of the Erasmus MC. At the time, the hoist shed was used for the construction of the 120-meter-high tower. One of the companies in the construction consortium was BAM Bouw & Techniek, which challenged us to take the construction method to the extreme in terms of scale, scope and functionality. For example, for the realization of De Zalmhaven I. The contractor reengineered the new tower into a completely prefabricated shell. An important condition for this innovative construction method."

Modular construction

"In close consultation with BAM Bouw & Techniek, we engineered the hoist shed for De Zalmhaven I and added the necessary functionalities," Van Vliet said. "In order to guarantee the multi-deployability of the hoist shed, a modular construction was chosen. Moreover, the shed is founded on four large steel jacking columns outside the building, allowing it to climb and descend building-independent. The jacking actions do not affect construction flows at all. From the shed, precast elements, floors and interior walls, cables and pipes as well as complete facade closure can be realized. This offers great planning advantages for the client. Computer control takes jacking technology to an even higher level."

Working comfortably and safely at height

The complete hoisting shed was built by Rijnstaal Nieuwegein bv; a sister company of Civiele technieken deBoer bv. "At the base is a modular steel main frame with solid work floors, which sits like a ring around the building," says Van Vliet. "The shielded structure is sealed against the building so that all construction site workers can work safely (at height). There is no chance of objects falling down. Moreover, work can be done under the best (climatic) conditions. Rain and wind do not affect the progress of work, which also benefits construction quality." The lifting shed for De Zalmhaven I was equipped with two 40-ton overhead cranes. "One crane - with a hook height of 200 meters - served as the main crane for all lifting movements from ground level, while the second assembly crane handled logistics within the shed. Because all lifting took place from a fixed position on the north side of the tower, lifting was always done within the construction fences; as far away as possible from all obstructions and the public area."

One floor per week

"With a drill you drill holes, with a saw machine you cut materials, and with a hoist you build towers in inner-city areas," Van Vliet outlines. "The goal was to complete a tower floor every week. This allowed the construction of De Zalmhaven I to be completed in 3.5 instead of 4 years. Every Friday afternoon we went to Rotterdam to lift the shed one floor in 1.5 hours." In October 2021, the tower reached its highest point and the hoist shed slowly sank back down. "The shed is engineered in such a way that it can be easily (de)assembled. For example, the roof of the shed can be opened and parking spaces are provided for the cranes, allowing the 900-ton hoist shed to lower freely from the building. Without risk of damaging the tower. During the jacking, steel column sections of about 6 meters are always added on top of the foundation pile, which can be easily removed again when lowering. So the table legs get shorter and shorter, until the shed is at the right height for disassembly."

At the moment, the modular lifting shed is in the garden of Civil Techniques deBoer bv, ready to be used on a new project. "Meanwhile, we are in talks with several parties," Van Vliet concludes. "The hoist shed will certainly go on to build another tower."