ABN AMRO roof extension with clay tiles on PET bottle facade elements

High-quality and reliable tile adhesive

Sopro Nederland B.V. is a leading supplier of construction chemical products. The company supplies, advises, and guides architects, contractors, tilers, and natural stone processors in using high-quality materials and techniques to achieve the best possible end result that meets all standards, from EC1 plus to BREEAM.

“We manufacture and supply cement products for the professional market,” explains Erik Koch, General Technical Manager at Sopro Nederland B.V. “From cement for fast-drying cement screeds to leveling compounds, cementitious adhesives, and jointing materials. But also: decoupling mats, epoxy, and cementitious and PU sealing layers. In short: the complete package for tilers and natural stone processors to deliver beautiful, high-quality projects to their clients.”

Impressive projects

Recently, Sopro Nederland B.V. provided advice and construction chemical products for the tiling work at the new headquarters of DPG Media in Amsterdam. Another impressive project is the renovation of the Jaap Eden Ice Rink in Amsterdam. Sopro Nederland B.V. is currently involved in the redevelopment of the ABN AMRO office in Amsterdam Zuidoost, which, upon completion in 2027, will become the green home base for nearly 11,000 employees. The building will also serve a social function.

Topping up with lightweight elements

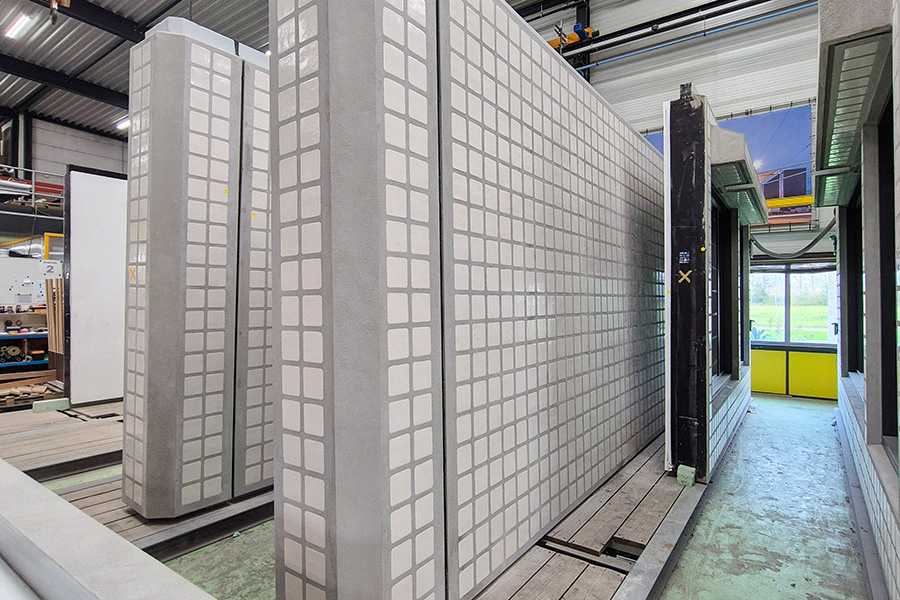

The ABN AMRO office will be renovated to be energy efficient and as circular as possible. For example, 70,000 m2 from the building will be reused, and many of the materials released during demolition will be repurposed. Another unique feature is that the two-story building will be topped up. “To save weight, a wooden main support structure was chosen in combination with Duplicor® integral facade elements from Holland Composites,” says Koch. “Particularly because of their sustainable nature, low CO2-footprint and high RC value combined with light weight and high structural strength.”

The Duplicor® Facade elements are combined with an original clay-fired and glazed tile finish, which honors the characteristic architectural value of the original building. “Because the old and new tiles had to match exactly in terms of shape, size, and glaze color, they were produced especially for this project by Dijkstra Friese Kleiwaren Sneek,” says Koch. “This company produces special sizes of tiles and glazed products in-house and entirely according to the client's wishes.”

Minimum weight, maximum reliability

Sopro Nederland B.V. was asked to contribute ideas for high-quality, reliable bonding of the tiles at Duplicor.® Facade elements made from recycled PET bottles and old plastic packaging. “A layer of reinforced bio-based epoxy is applied to this recycled core, after which the entire facade element is baked in an oven at a temperature of 120°C,” explains Koch. “The result is a smooth surface. That is why we first supplied an epoxy primer, which was sprinkled with fire-dried quartz sand to ensure sufficient grip on the material. The tiles were then bonded using a two-component powder adhesive – Sopro MEG 667 TX – to which a dispersion was added instead of water.” The tiles were then washed with a jointing material, which is wider than one centimeter and also seals the joints.

Support and quality control

Sopro Nederland B.V. tested the combination of facade elements, tiles, and construction chemicals in advance in its own laboratory in Germany. “Both tensile tests and adhesion tests were carried out,” says Koch. “Because we cannot be the judge of our own work, contractor BAM Bouw en Techniek also had a successful test carried out by the independent testing institute TCKI. Prior to installation, we clearly explained how our products should be used. We also worked alongside the installation team for a few days to ensure cavity-free bonding in accordance with the buttering-floating method. This was to prevent water accumulation behind the tiles, for example. A number of unexpected interim checks were also carried out so that adjustments could be made on site if necessary. This ensures optimal delivery quality.”

Start of a close collaboration

The ABN AMRO office was the first project in which Sopro Nederland B.V. and Holland Composites collaborated, but it certainly won't be the last. The companies are now working on several other projects. “This is hardly surprising, given that lightweight construction is becoming increasingly popular in our country.”