Comfortable and sustainable indoor environment

The realization of a comfortable and sustainable indoor climate for the final part of the new Rotterdam Logistics Park (RLP) distribution center in Hellevoetsluis was the core of Vink Installatie Groep's assignment. Thanks to its previous involvement with building sections B and C, the principles, ambitions and working methods were already familiar.

“Together with a fixed group of chain partners, the focus from the start was on quality, sustainability and efficiency,” begins Corné van der Kwaak, project engineer at Vink Installation Group. “With the aim of creating a pleasant working climate for the users and a future-proof building for the client. Earlier, we also realized building parts B and C on behalf of Heembouw. That cooperation formed a solid basis for building parts A and D.”

WTB and plumbing

Within this project, Vink Installation Group is responsible for the mechanical and sanitary installations. “Specifically, this means that we are taking care of the rainwater drains, indoor sewers, water installation, fire-fighting installations, heating, ventilation, cooling and control technical installations,” says Van der Kwaak. “The industrial hall is heated, as are the offices, where there is also the option of cooling. For this, we use an air/water heat pump for each building. Air handling units are used for ventilation in the offices.”

Simulation calculations

According to Van der Kwaak, the Program of Requirements was drawn up in consultation with the client. “Because this had already been worked out for building sections B and C, it could be used as a basis and adjusted for each building. In addition, additional BREEAM requirements were added, which affected energy consumption and comfort, among other things. For example, simulation calculations were made to predict the expected climate experience and a practical measurement is carried out upon completion. In terms of water conservation, toilets with low flush volumes, leak detection and automatic shut-off valves, among other things, have been applied.”

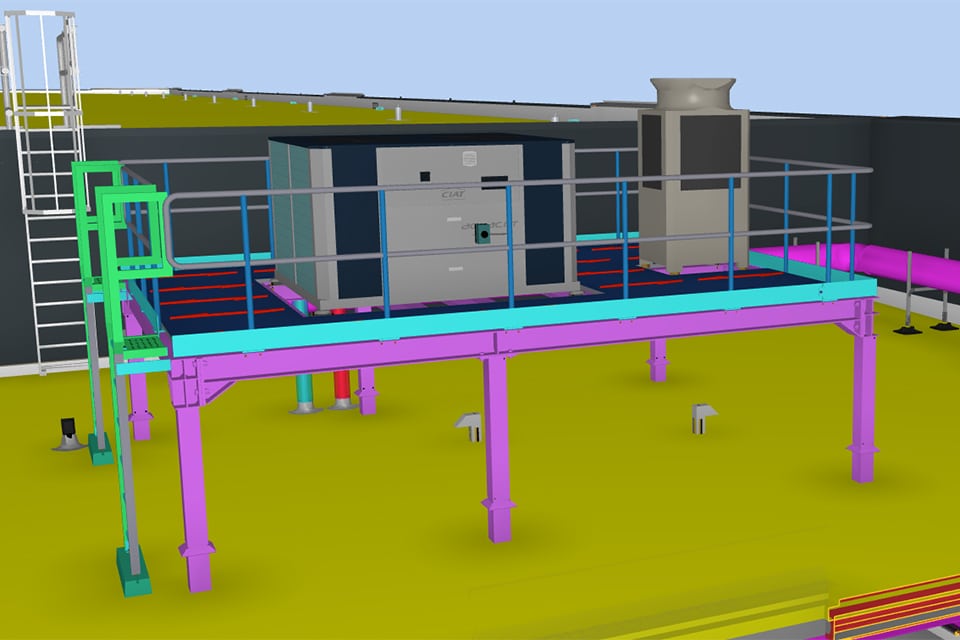

The biggest challenge within this project is planning, he states. “In the preliminary phase, the distribution center was completely digitally worked out in a BIM model, including mechanical and sanitary installations. This allowed clashes to be resolved early and kept the planning feasible.” Vink Installatie Groep further prefabricated much of the piping, which saved time on site. “What makes this project special for us is not so much the technology, which is familiar, but the efficient collaboration, BIM approach and prior knowledge from earlier phases. That makes it possible to deliver quality within a tight schedule.”