Quality and efficiency come together in electrical installation for TU/e campus

As of the 2024-2025 school year, the TU/e campus in Eindhoven will have 735 new student residences. Commissioned by contractor Heijmans, Van Hees Elektrotechniek & ICT realized the electrical installations in the two new residential towers and the intermediate low-rise buildings. "Our installations are not only perfectly matched to the target group, but also to its use," says Paul Kot, project manager at Van Hees Elektrotechniek & ICT. "After all, the tenants of these apartments will change regularly."

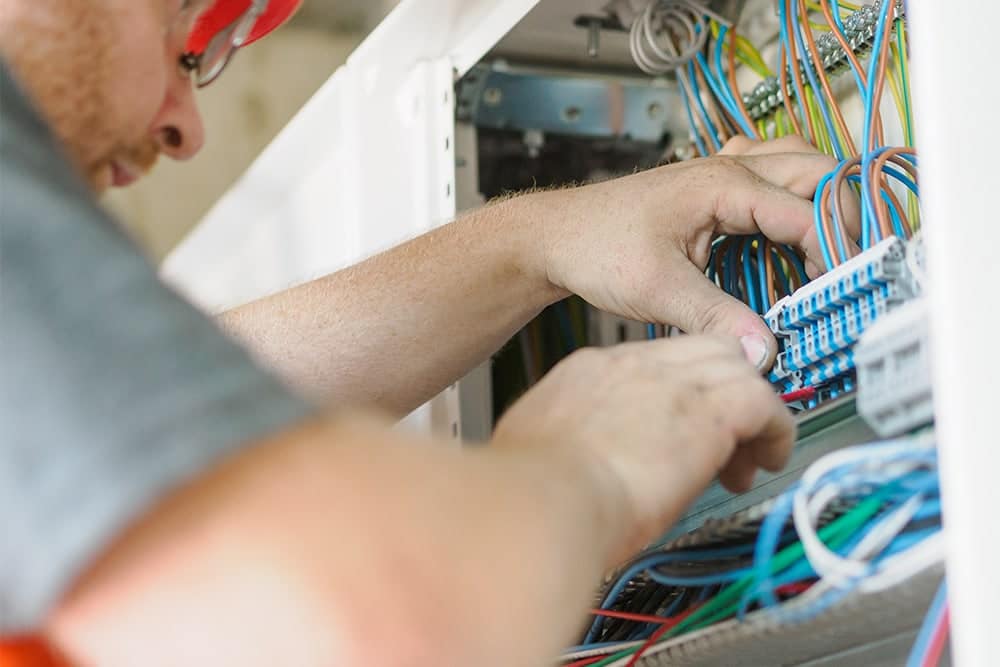

Van Hees Elektrotechniek & ICT realized an electrical installation of stature in just fifteen months of construction time. "Our installation package ranges from the cables in the ground to the complete electrical infrastructure in the three building sections," Kot explains. "From the student residences to the general areas and from the main and sub-distributions to the (emergency) lighting, escape route signs, access control and intercom systems, data installation, power supply for the solar panels and bus control cables for the heat pumps. For the commercial space in Tower West, we delivered the installation shell, allowing the user to finish it as they saw fit."

One challenge in particular was the size of the project, says Michiel Gersjes, director of Van Hees Elektrotechniek & ICT. "Actually, we were dealing with three projects that had to be realized at once and in a relatively short time. This required good communication and coordination. Both with our own mechanics and with the main and side contractors." Van Hees Elektrotechniek & ICT worked with a total of sixteen mechanics on this project. Kot: "In order to properly coordinate all work in advance, the entire project was first modeled and clashed in 3D/BIM. The preparation took about a year."

To ensure fast construction, a prefabricated construction method with precast concrete walls and precast concrete floors was chosen. "The pipes for our cables were already cast into the concrete floors at the factory," Gersjes and Kot explain. "On our advice, fixed rather than flexible pipe was chosen, which allowed us to perform our work well and quickly. Thus, quality and efficiency were chosen in every area."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Van Hees Electrical Engineering & ICT.

Contact opnemen

Contact opnemen