Long collaboration bears fruit

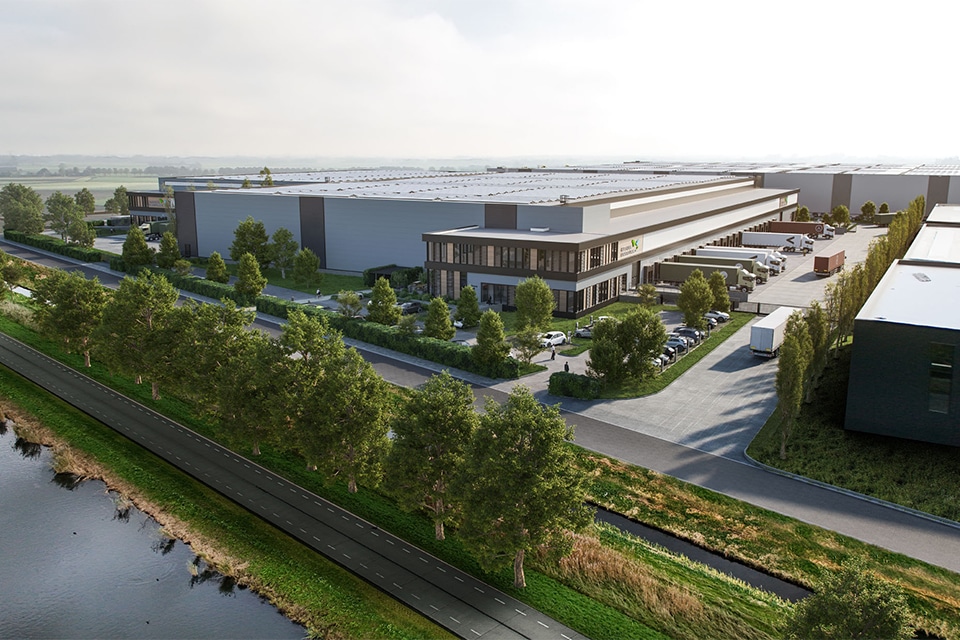

When Leen Menken Foodservice Logistics wanted to expand with a cold store, RBK Group was the logical choice. In fact, the foodservice company has been a client for over 20 years and now engaged RBK again for the design and development of the cold store. Hans van den Hoorn, architect at RBK Group, talks about this project.

RKB Group is a Deventer-based consulting and automation company that has specialized in the food industry for over 40 years. RBK not only has architectural expertise, but also knows everything about installations and permits, as well as developing its own software. "In terms of design, advice and automation, we are a kind of one-stop-shop for the food industry. As a result, our customers are not dependent on different suppliers and parties," Van den Hoorn says. "We find it important to look not only at the construction task, but also at the future use. For an (energy) efficient and well-functioning building, an integral view of the building and its installations is crucial."

Sliced cake

Designing not only the new freezer building but also the software control of the refrigeration system was cake for RBK, says Van den Hoorn. "The world of refrigeration and freezing is not unique to us, but rather our expertise. The challenge lay mainly in the location, because we had to take into account an existing building, a tight building plot and our client's growth ambitions. Among other things, this led to the large cantilever at the front of the building."

That more creative solutions were devised is evident in the street façade of the freezer house. "The client wanted windows at the front of the building. However, the indoor temperature here is -20°C, and you obviously want to prevent the windows from condensing or freezing. After some puzzling with double windows and heating, we still managed to provide the order picking areas with daylight this way."

Sustainability central

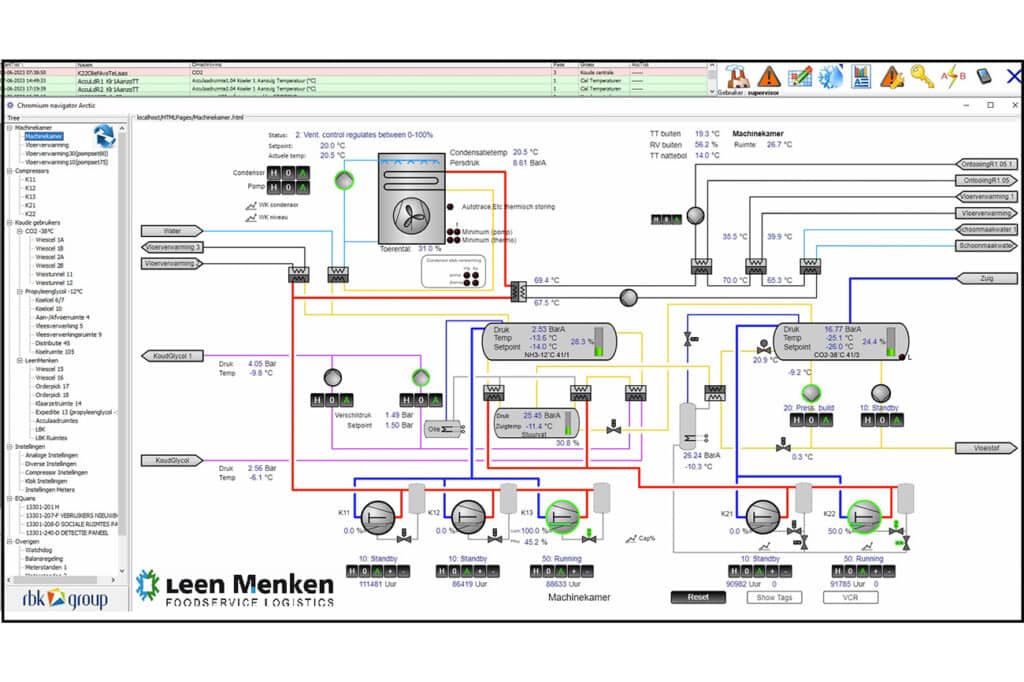

According to Van den Hoorn, the new cold store was built with sustainability in mind. "Large refrigeration and freezer rooms naturally require a lot of energy. We chose not to build a new machine room, but to use - with the necessary modifications - the neighbor's existing machine room and refrigeration installation. This saves space in the new building, and also ensures that only one installation needs to be powered. Furthermore, much of the electricity is generated by solar panels on the roof, and we use the heat released from the cooling installation to heat the offices. Finally, RBK also provided the control and regulation of the central cooling installation. In this way, Menken saves significantly on energy use and energy costs."