Cut from the right cloth

In Almere, Restaurant Festijn is expanding with the Wooden Hotel. Mirck Architecture was looking for a company with the same penchant for wood construction. Then FLETTS is a logical choice! Dennis van Lith, initiator of FLETTS, talks about this project.

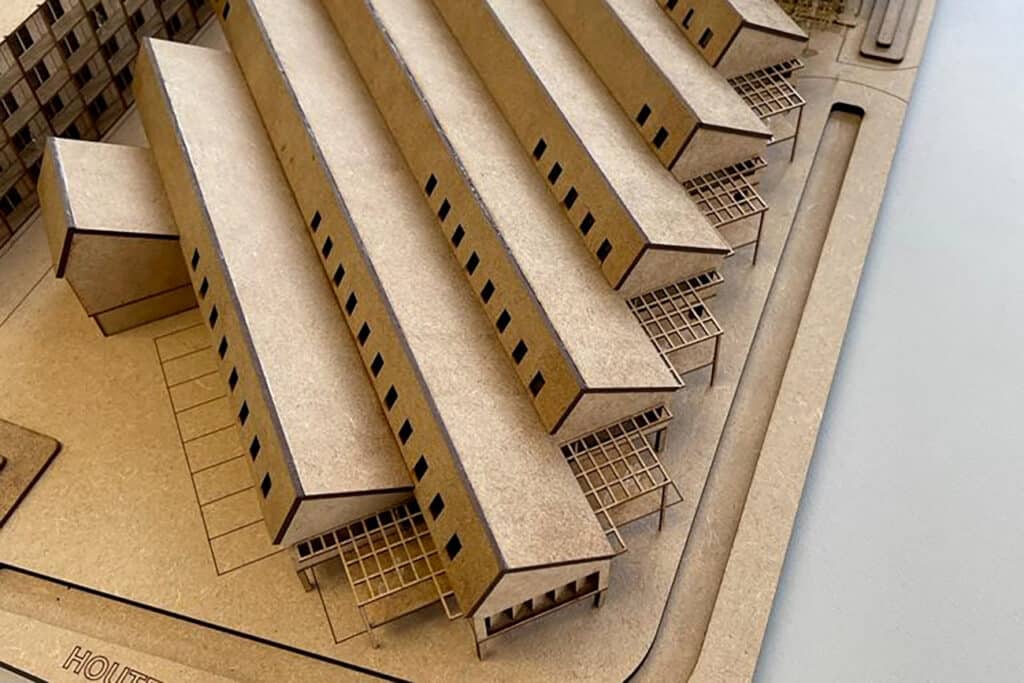

The Wooden Hotel has 172 rooms, and sustainability is at the heart of it. "The two buildings are almost identical and four stories high," Van Lith says. "From the first floor up, everything is made of wood. Natural materials are the basis, so we use a lot of CLT and HSB for the construction and the facade finish is bamboo. Unless it's really necessary, we prefer not to use steel or concrete."

Quietly unwind

The choice of wood does require a lot of creativity. "The biggest challenge of building with wood is noise. In stack construction, it's important that you don't experience nuisance from your upstairs or downstairs neighbors. Because wood is very light, it lets more noise through, and we had to find an alternative to solid concrete structures that dampen more noise. This is where CLT is perfect: cross-laminated wood that is as strong as concrete. Combine it with Scandinavian insulation techniques and you get soundproof rooms where every visitor can unwind."

Different from other projects

FLETTS' approach differs from what we are used to in construction, Van Lith says. "I first worked in traditional construction, but didn't always agree with that world. That's why I continued on my own with my vision and way of working. For example, we take the lead fairly early in the project. Other projects often involve several parties who have to coordinate everything with each other. We want to deliver a product where design, energy efficiency, comfort and practical construction planning have already been thought out. By involving the various parties early on and integrating them into our own team, a product can be ready very quickly."

Good preparation

This quick turnaround time is characteristic of FLETTS. "We regularly hear that people are surprised at how fast the work goes on site. Before we even start on site, we are already prefabricating the entire building. The load-bearing walls, facade elements, bathrooms and the roof are all already made and we deliver them ready to go. The glass is already in the frames and the bamboo is already attached to the facade. All we have to do on site is screw together the structure."

Prefabricating the building also has other advantages. Because everything is pre-made, the construction itself is very quiet. "We have a small team that puts the whole building together. Everyone knows exactly what to do. Because the work consists of screwing the various parts together, there is virtually no noise pollution for the surrounding area. We even use an electric crane and make sure that the delivery of the parts is planned so that there is as little inconvenience as possible. This is how we take sustainability and the immediate environment into account with our projects."

- Client Festijn Culinary Real Estate B.V.

- Architect Mirck Architecture

- Constructor Van Roekel & Van Roekel (lead structural engineer), Solid Timber (timber structural engineer)

- Contractor FLETTS B.V.

- Installations Projects Support B.V.

- Construction period November 2022 - July 2023