Brick producer embraces dry-stacking technique

Rodruza's factories have been baking bricks in the Netherlands for several hundred years. Innovating in time is important to the family business. This manifests itself not only in a wide range of products, but also in increasingly sustainable production processes and the adoption of sustainable solutions, such as recently the technique of dry stacking and the use of reusable pallets instead of disposable pallets.

"The history of brickmaking is centuries old," says Frank Struijk, sales consultant at Rodruza. "The oldest buildings constructed from brick are more than 8,000 years old. It is an incredibly durable product. Yet it is important to keep innovating and making it more sustainable, without losing sight of the history of the Dutch brick industry." That is the reason Rodruza is making the shift from purely a brick manufacturer to a full-fledged fulfillment supplier of bricks.

Infinite resource

The basis of the brick is river clay; a self-renewing raw material. "And that has been scientifically proven," says Struijk. "The deposition of river clay is a continuous process. So clay never runs out, as long as the rivers keep flowing. In fact, if we as brickmakers don't keep mining the clay, the Netherlands will even get wet feet." Rodruza largely uses Dutch river clay, but also uses a German clay component for some grades of brick to arrive at the extensive assortment of now some 180 different grades. "The basic color of the brick is determined by the clay combined with various ceramic treatments, with the gas used to fire the kilns also being a color component. So when it comes to preservation, the latter is also a serious aspect to consider."

Sustainable and circular

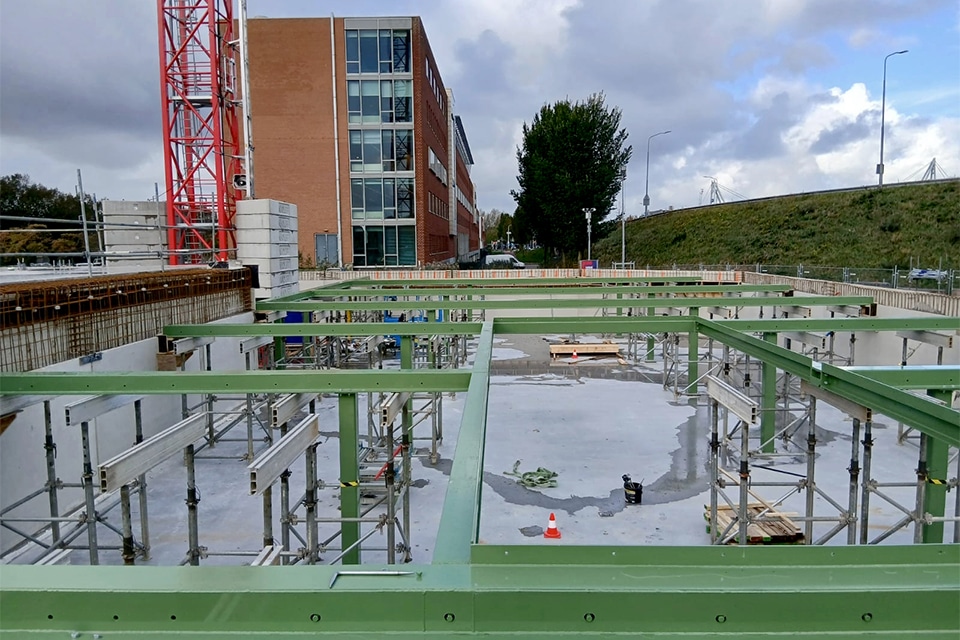

Reinout Lempers, director of Drystack, says, "Rodruza is the first brick manufacturer to adopt the Drystack concept and proactively enter the market with its relations. The Drystack concept is delivered ex-factory. The bricks are fitted with cut-outs to allow for circular processing." It makes the facade 100% reusable, Struijk assures. "The concept relies on special 'layers' (coupling anchors, ed.) made of recycled plastics that fit precisely into the recesses of the bricks. There is no masonry mortar involved. Drystack can also be processed without joints. And that, of course, is the biggest environmental gain when you consider that a regular facade consists of approximately 22% of grout. Drystack can further be processed under all weather conditions, no water is required, resulting in a clean working environment with virtually no waste."

A pioneer in the industry, Rodruza has embraced the Drystack concept to create a sustainable future for brick. Meanwhile, the first works are already in progress. Almost the entire Rodruza product range is therefore suitable for drystacking. According to Struijk, the concept is competitive with traditional masonry and is processed exclusively by certified "stackers. "Because no masonry mortar is used, it is a very interesting product for the earthquake area in Groningen, but also as a circular and weather-resistant exterior shell for timber frame construction. Drystack also gives architects the freedom to come up with the most creative solutions with the 'age-old' brick." Rodruza delivers the system as a complete package to the construction site.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Rodruza B.V..

Contact opnemen

Contact opnemen