On the way to energy label A

Captain flats in Zwijndrecht are being prepared for a sustainable future

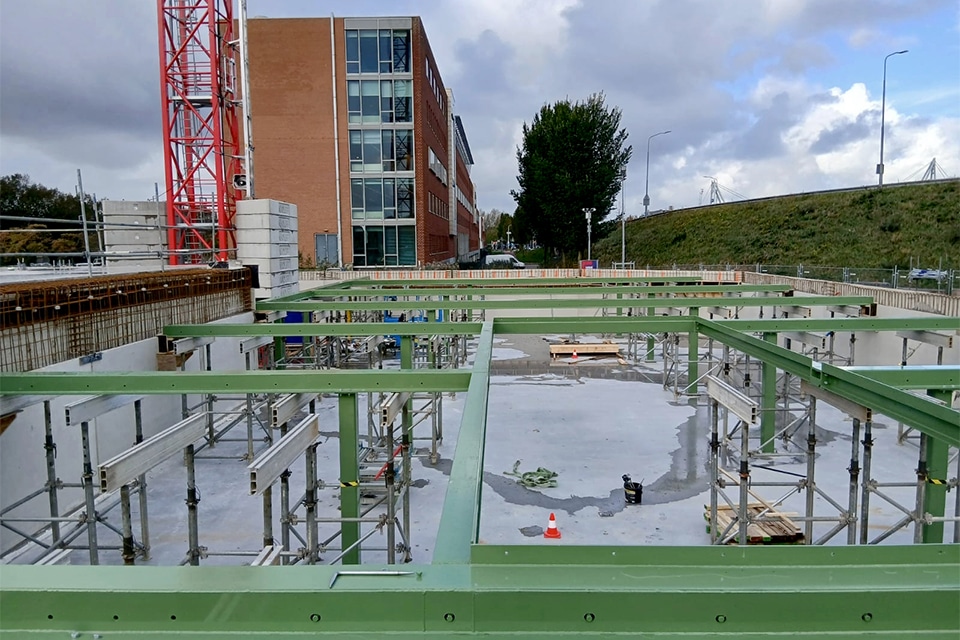

In Zwijndrecht, 355 homes in the Kapitein Horsmanflat, Kapitein Luidingaflat, Kapitein Stamperiusflat, Kapitein Rietbergenflat and Kapitein Dekkerflat are being radically improved and prepared for a sustainable future. An important part of the work is the insulation of the front and rear facades, storage ceilings and roofs. The homes will also be fitted with a heat pump boiler, CO2-controlled mechanical ventilation and new front and balcony doors. In close cooperation with Hemubo and housing corporation Trivire Wonen, Facédo is replacing all uninsulated aluminum window frames with plastic window frames with HR++ insulating glass. Thanks to this and other work, the homes can be completely off the gas. In addition, the residents' comfort will be considerably improved.

In total, Facédo is supplying and installing approximately 5,000 m2 of window frames in the Kapiteinflats. "At the basis of these window frames is the recessed K-Vision Trend window frame series, which is characterized by a contemporary and slim design, excellent burglary resistance and hinge parts that lie in the window frame's negge," says Ben Slebus. "Of course, the window frames meet all current standards for thermal insulation and airtightness. They reduce heat loss in the homes and increase energy efficiency and living comfort. The plastic window frames and turning parts have joints that are completely homogeneously welded. The base profiles are colored throughout in a traffic white color, resulting in high durability and easy maintenance."

Results Oriented Collaboration

Slebus worked as a construction site manager and foreman at Facédo for more than 11 years and is now enjoying retirement. Still, he did not want to miss out on the improvement maintenance of the Kapiteinflats, he says. For example because of the scope of the work, in combination with the pleasant cooperation with Hemubo and his Facédo colleagues. Facédo started the assembly work just after the 2023 construction period. The work is carried out according to the Result-oriented Cooperation (RGS) method, which focuses on high quality and sustainability, better working methods, optimum safety and minimum failure costs. Per day, Facédo's fitters tackle two homes. "Prior to the work, two model homes were built, corresponding to the four housing types. As a result, residents know exactly what work will be carried out in their homes and what they will receive in return."

Digital recording and delivery

Prior to the work, all homes will be digitally recorded in HomeDNA. "This allows the so-called zero measurement to be taken immediately at the start of work in the morning," Slebus said. "At the end of the day, once we are finished, the frame replacement is also delivered digitally according to the HomeDNA protocol. Should there be any changes in the future, it is very easy to read out the relevant history at house level, per frame and based on a unique ID reference. This guarantees efficient complaint handling."

Finishing touch

Following the plastic window frames, Facédo also provides the various typesetting work to complement this preservation. "For example, we replace the old window sills with aluminum water sills, in the same color as the facades," Slebus says. "In addition, we provide the finishing work on the inside of the houses. The choice was made for Progé window frame day sills made of moisture-resistant MDF and with a luxury finish film, which means that no further post-treatment is necessary. The reveal trim is cut to size on site. A sealant edge here provides the finishing touch."

All aluminum window frames and glass coming from the 355 homes are carefully separated and offered for recycling. For example, for the production of new insulation windows. The final work will be completed by the end of this year, after which the window cleaner will be able to clean the windows and residents will be able to enjoy their new comfort.