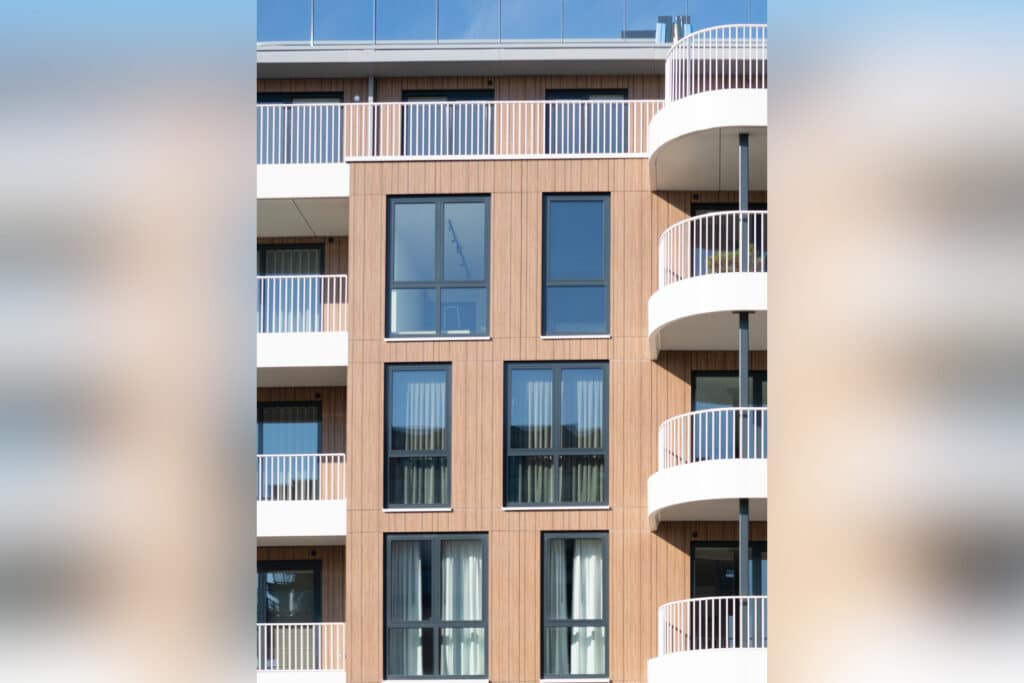

Intal realizes custom window frame solutions for prestigious Zalmstael residential building in Maassluis

For the Zalmstael luxury residential building in Maassluis, Intal supplied high-quality window frames and curtain wall facades, which are fully aligned with the sleek and open architectural design. In collaboration with contractor Waal, Intal ensured an efficient and sustainable construction process, with smart prefabricated solutions and custom aluminum façade elements.

Exclusive architecture with curved glass

With spacious apartments and penthouses equipped with special features, Zalmstael stands out within the Maassluis skyline. The corners of the large fenestration at the penthouses feature curved glass, providing spectacular views of the water. "Intal curtain walls were used here for an open and transparent appearance," says Robbert de Nijs, Project Manager of Major Work at Intal. "In apartment buildings, curtain walls are usually less common. We delivered standard profiles in custom designs tailored to the specific technical requirements and architectural wishes of Zalmstael. It's a nice mix of our own Intal Therm profiles, IT55 curtain walls and IT77ST window frames."

From traditional assembly to prefabricated solution

Originally, the approach was to process the window frames traditionally on site, but together with Waal, Intal sought a more efficient approach, "because Waal wanted to incorporate the window frames at a different point in the construction cycle," De Nijs said. "This led to the decision to pre-assemble the window frames in prefabricated wooden cavity walls. This allowed for faster and more accurate installation on site and reduced the margin for error. This shortened construction time, increased quality and saved costs."

Intensive preparation and engineering time

"The switch to pre-assembly in the carpentry factory required an intensive preparation process together with Waal," says De Nijs, explaining, "We applied project-specific solutions in the detailing and optimized the profile technically for a smooth assembly process. For example, we disconnected certain components so that the frames could be installed first and then the other elements. In addition, the large sliding doors played an important role in the technical elaboration. These were surrounded by a very slender HSB element, making transport and installation an additional challenge."

Lean and just-in-time

Salmonstael was realized using a lean working method, with all parties involved contributing their expertise at an early stage. This ensured efficient coordination between design and execution. "In addition to the smart prefab approach to the window frames, the logistics were also optimized in detail," says De Nijs. "Through a just-in-time delivery strategy, the precast elements arrived at the construction site at exactly the right time. This minimized storage and handling and ensured a streamlined construction process." Waal also emphasizes the importance of this approach. "Lean in optima forma," says the commercial project manager. "Not just the processing of the window frames, but throughout the entire process - from engineering to completion. The flow of materials was perfectly coordinated, so the right elements were integrated into the precast cavity walls exactly on time."

Successful partnership

Project Zalmstael shows how innovative techniques and good cooperation lead to optimal results. The architect's vision is well translated into the built environment, adapted to sound advice, without making concessions on quality or appearance. "The close cooperation between Intal and Waal was crucial in this project," concludes De Nijs. "Our previous projects within De Kade Maassluis laid the foundation, but Zalmstael represented a new milestone. It shows how thoughtful customization, innovative assembly solutions and a strong partnership take a construction process to the next level."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Intal.

Contact opnemen

Contact opnemen