The Blox as a blueprint for the new building practice

Prefab energy skids

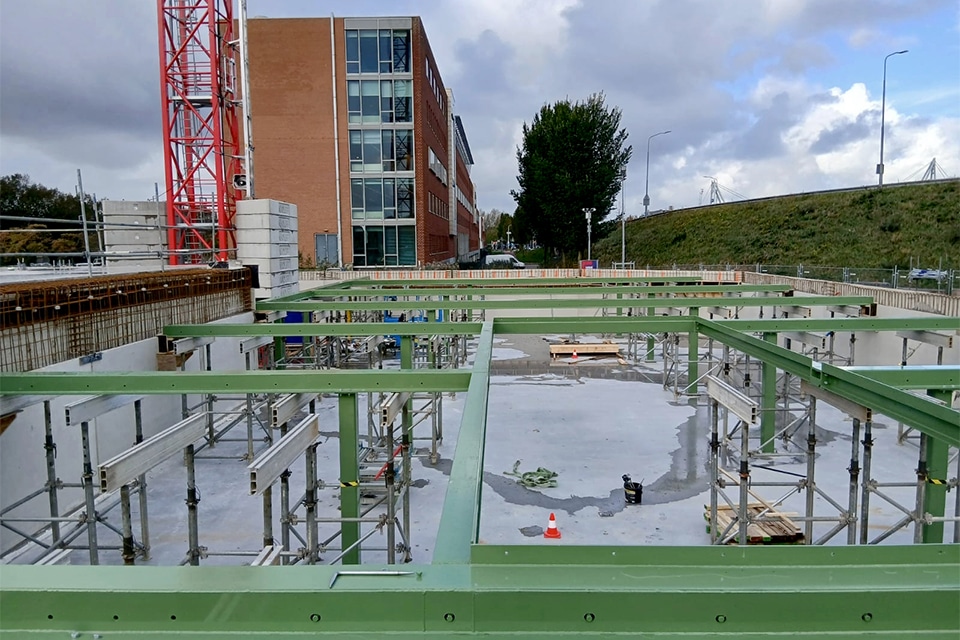

In The Hague, The Blox is rising, a sleekly designed residential complex that is being built completely differently in terms of WKO technology than the sector was used to for decades. Not with loose pipes, three different teams and endless coordination on the building site, but with ready-made prefab energy skids from ERA Prefab Systems. 351 of them, fully engineered, tested and ready for installation. “And this is not a gadget, but a trend break,” says Eduard Aubri of ERA Prefab Systems. “Prefab is no longer a choice, but a necessity.”

The industry is under tremendous pressure, according to Aubri. “There are too few skilled workers, installations are becoming increasingly complex and failure costs are growing. In Austria, where our precast roots are, we worked with precast concepts that made so much sense that, by returning during corona in 2020, we decided: we are going to continue this knowledge and experience in the Netherlands.” Since then, ERA has grown into a specialist in industrial energy modules. Not as an assembly company, but as a factory of standardization.

Energieskids as a product

ERA's prefabricated units are full-scale products, engineered, built and tested under factory conditions. Each unit includes a complete cold and heat distribution, positions for metering/energy unit, fittings, safeguards and controls, a factory-set hydraulic configuration, connections for apartments and QR identification with a digital data card. The units come off the production line in Almelo with uniform tolerances and repeatable quality that is simply not achievable on the construction site.

20 minutes of assembly

Where a traditional installer takes an average of a week, ERA installs an energy skid in about 20 minutes. Aubri: “Not because we want faster, but because the process is different. Everything is done in advance. No improvisation, no puzzling, but a product that fits.” The result: independent planning from side contractors, virtually no failure costs, fewer transport movements, peace and quiet on the construction site and a predictable rhythm for contractors. “Construction no longer has to wait for the installer,” says Aubri. “We come, install, connect and finish fireproofing - and construction can go on.”

Circular thinking

Each module has a unique QR code with revisions, serial numbers, parts list, test results, location in the building and additional technical data. In the event of renovation or demolition, this makes reuse easy. “A module is no longer a bricked-in system, but an element that can be reused. That is truly circular construction,” Aubri said.

Vertical standardization

For The Blox, ERA supplies 351 prefabricated energy units. This assembles the complete vertical installation part in one movement. In this project, ERA is working directly on behalf of Eneco. The horizontal installation - the pipes in floors - will be carried out later by other parties, but the heart of the energy system comes from the prefab factory in Almelo. In addition, ERA is building project-specific solutions: from hotel modules with heat pump and ventilation to total frames for sanitary functions.

Stability

Why clients are switching to precast? According to Aubri, the gain is not only in speed. “Prefab means stability. You build with certainty, not variation. That's what clients want: predictable, plannable and repeatable. The industry is at the beginning of a major shift, and precast installation technology is a logical part of that.” The growth is visible: energy companies, developers and contractors are increasingly seeking collaboration to achieve one uniform standard. “That is also exactly what we are doing now with Eneco and Vattenfall. We are building something that will be bigger than one project.”

A new building practice

More and more projects show that prefabricated design is not the future, but the present. For ERA, The Blox is not an endpoint, but an intermediate step toward a construction industry that thinks entirely industrially. Aubri sums it up, “We deliver prefab design technology like cars are made: factory-made, tested and with repeatable quality. It's faster, smarter and better for the climate. It's just the way it should be.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met ERA Prefab Systems.

Contact opnemen

Contact opnemen