New bol.com building meets highest standard for sustainability and working conditions

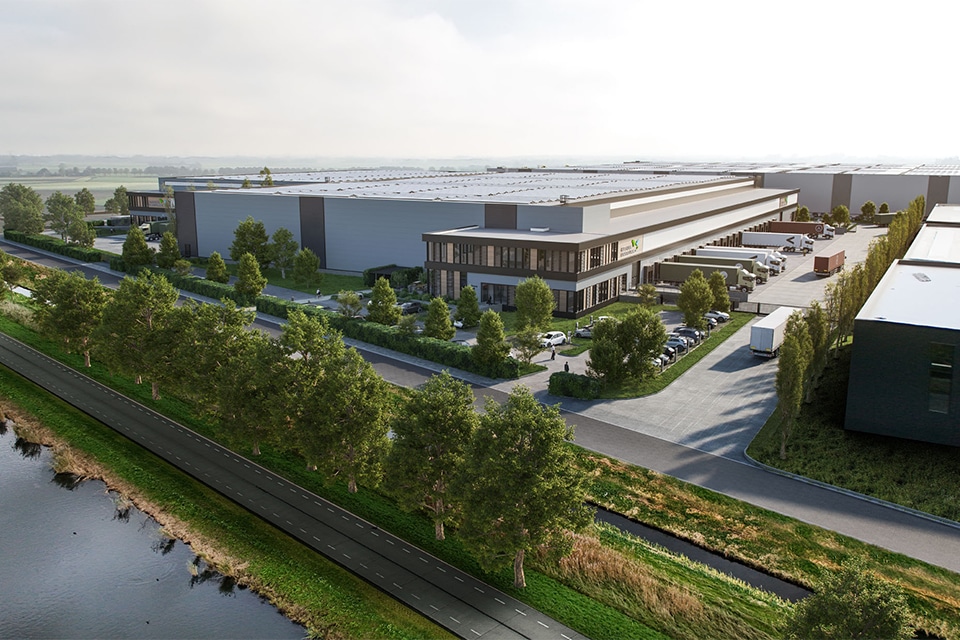

To keep up with the growth of Internet purchases, a second, fully mechanized distribution center is being built for web store bol.com at Haven Acht business park in Waalwijk. The new building was architecturally completed in July.

Text | Lieke van Zuilekom Image | Construction company van de Ven

In the coming months, the (mechanical) setup and testing will be completed and new employees will be trained and inducted, after which the first packages are expected to roll off the belt in 2021. New building BFC2 is linked to bol.com's existing 2017 fulfillment center (BFC1), expanding the total complex from 50,000 to 100,000 m². The expansion, like the existing construction, will meet the highest possible standard for sustainability and working conditions.

"Thanks to the additional surface area, the more than 30,000 partners who sell through bol.com will be able to make use of all the advantages offered by the fulfillment center, such as storage, innovative packaging, sorting and effective logistics," says Rick Kromwijk, project manager of BFC2. "The construction of the expansion is completely in line with our existing fulfillment center and is once again taking place according to BREEAM-NL 'Outstanding' guidelines. During both the design and construction, optimal daylighting, optimal walking distances and minimal environmental impact were central. And optimal working conditions are also paramount when it comes to the innovation of mechanization. For example, goods will move to the workers instead of the other way around, further reducing walking distances."

Professional and flexible

The new building includes space for a goods receiving area, warehouse space and distribution space. At the front, two office floors have been set up; the rear has one office floor. In addition, pit stops and a control room have been realized at strategic locations in the distribution center. The construction work, site layout and installation techniques were awarded by bol.com to Bouwbedrijf van de Ven. The contractor from Veghel also has a coordination obligation towards bol.com's subcontractors, who are responsible for the assembly of the conveyor belts and the (mechanical) warehouse equipment. The choice for Bouwbedrijf van de Ven was a logical one, according to Kromwijk. Not only because of its extensive experience in building (mechanized) distribution centers, but also because of its professional and flexible attitude. "Building a complex project like this, in which construction and mechanization must form one whole, combined with the very short timelines requires a contractor who proactively thinks along in solutions. Bouwbedrijf van de Ven absolutely does this. We are particularly enthusiastic about the no-nonsense mentality, where the contractor does what he says."

To keep up with the growth of Internet purchases, a second, fully mechanized distribution center is being built for web store bol.com at Haven Acht business park in Waalwijk.

2,300 foundation piles

"We were involved in the new building at an early stage in order to optimally coordinate the structural elements, installation techniques and mechanical design for the new distribution center," says Rob Gielis, project manager at Bouwbedrijf van de Ven. "For this we used, among other things, a 3D/BIM model, for which the structural engineer and installation parties also provided their input. We carried out regular clash checks, which minimized start-ups and failure costs during execution. In January 2019, we started the ground and foundation work, during which as many as 2,300 foundation piles with a total length of 26.5 kilometers went into the ground. Then the assembly of the steel structure could be started."

5.6 million pounds of steel

"In just seven months, a steel structure totaling 5.6 million pounds of steel was built, including about 60,000 sq. ft. of hollow-core slab floors," Gielis says. "Some 1,200 trucks were needed to transport the steel and floors to the construction site. Sandwich cladding was chosen for the facades. And cladding panels were also used on the roof, finished with TPO roofing and fitted with PV panels. After the building was wind and watertight, the first floor and the pressure layers of the floors were poured, for which a total of 21,750 m³ of concrete was delivered. The loads on the first floor are borne on approximately 5,700 floor piles."

BREEAM-NL 'Outstanding'

In October 2019, bol.com started moving in all the equipment. At peak times, up to 400 tradesmen were running on the construction, Gielis says, which demanded good coordination, cooperation and alignment. "Thanks to the great commitment of our tradesmen, subcontractors and bol.com, we managed to meet all milestones in accordance with the contractual agreements." To meet the BREEAM-NL 'Outstanding' criteria, all trips to and from the construction site were recorded. "On construction, waste was also strictly separated and we worked with sustainable materials wherever possible. LED lighting was used in and around the building and there are PV panels on the roof. A dual-source CHP system provides sustainable heating and cooling for the building."

Construction Info

Client Ahold Delhaize/bol.com

Design and construction management DENC Netherlands

Contractor Construction company van de Ven

Constructor Pelecon

Subcontractor installations Hoppenbrouwers Techniek (E), Terberg Total Installations (W), Altebra Sprinkler Technology (sprinkler)

Floor elements VBI Sales Company

Stairs and railings Van der Lee Metaal B.V.

Roofing A. van Diessen Roof Coverings

Aluminum window frames JM van Delft & Zn

Project info

High quality aluminum facade elements

Following the existing fulfillment center and commissioned by Bouwbedrijf van de Ven, facade builder JM van Delft & zn produced, delivered and assembled the aluminum frames, windows, doors and curtain walls for bol.com's new distribution center.

"At the basis of our products are high-quality and sustainably produced Schüco profiles, which we process ourselves into complete façade elements," says Remco Kastelijn, project manager at JM van Delft & zn. "The many strip windows were transported to Waalwijk in elements of 4 to 5 meters and coupled on site." Part of the project was carried out with ScreenLine glazing, in which motor-controlled llamellite blinds were installed between the double insulating glass. "In addition, much of the window frames are fitted with solar control glazing, which actively keeps heat out while allowing employees to benefit from maximum daylighting. The north façade of the project is equipped with regular HR++ glass with a U-value of 1.0, ensuring a high insulation value."