Dust-free warehouse floor

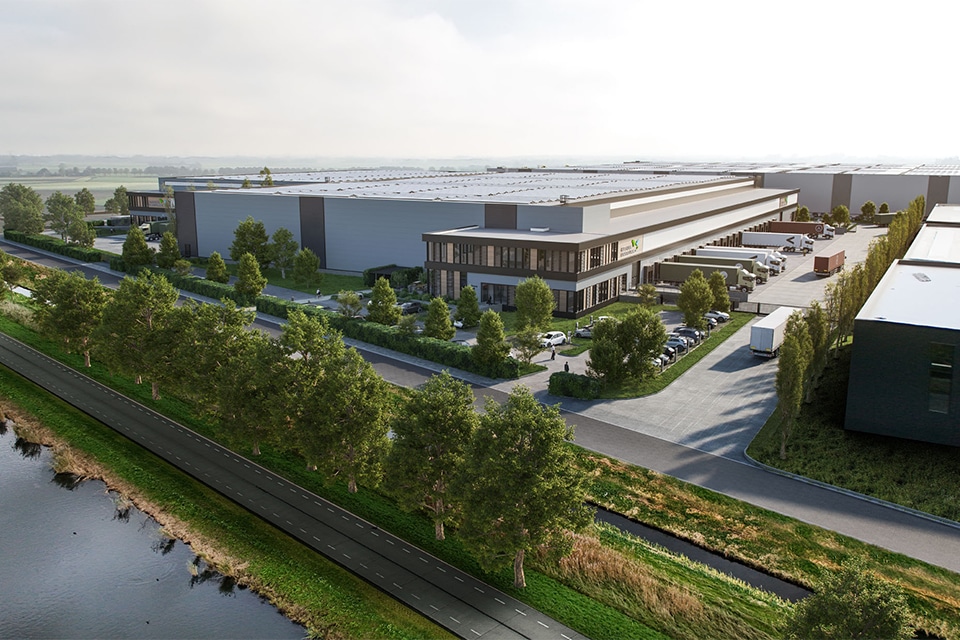

Thanks to a balanced floor design and the application of a special dust binder on the top layer of the floor construction, the supplier of hygiene products will soon be assured of a dust-free warehouse floor. An interview with Jeroen Boers of Twintec Nederland, responsible for the installation of the monolith floors with a ten-year performance guarantee.

Twintec is providing the new distribution center with some 26,000 m2 of monolithic floors, of which more than 19,000 m2 of warehouse floor will be executed as a hybrid floor with base reinforcement and steel fibers in flatness class DIN 18202 zeile 4. "The basic design of the floors on piles was prepared by ABT, a renowned engineering firm skilled in floor design," says Boers. "We took the basic design, checked it and developed it further to ultimately issue our Design, Build and Guarantee performance guarantee on the end result. It means for the end user that they don't have to worry about the floor for 10 years."

Game of engineering

The floor design is characterized by a fairly large pile grid, Boers says. "To achieve a balanced design, we use pile head reinforcement. At the location of the piles, the floor is weighted to accommodate the point loads in the floor. This avoids having to make the entire floor thicker. So it is truly a game of engineering to achieve the most optimal result. A total of 5,000 m3 of concrete will be processed in fifteen phases. The warehouse floor is realized in nine pours, the loading pit construction (3,000 m2) in two pours and the compression layers (4,000 m2) in four pours. The warehouse floor is provided with a dust binder one day after pouring. This gives additional hardening to the top layer and prevents premature wear and therefore dust formation."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Twintec.

Contact opnemen

Contact opnemen