Another highly sustainable DC for Lidl in Almere

About 50 percent of the warehouse consists of refrigerated and freezer rooms, where, for example, meat, dairy products, vegetables, fruit and chocolate are stored at a specific temperature. The remaining spaces are for perishable products. In addition to the enormous size of the distribution center, the sustainable nature of this new building makes it particularly special, says Leo Mosselman, project leader at Bouwbedrijf Vrolijk. For example, there will soon be nearly 7,000 solar panels on the roof, no natural gas will be consumed, all lighting will be 100% LED, and the building will receive a BREEAM-NL 'Outstanding' qualification. "Upon completion, the new building will be among the most sustainable distribution centers in the Netherlands."

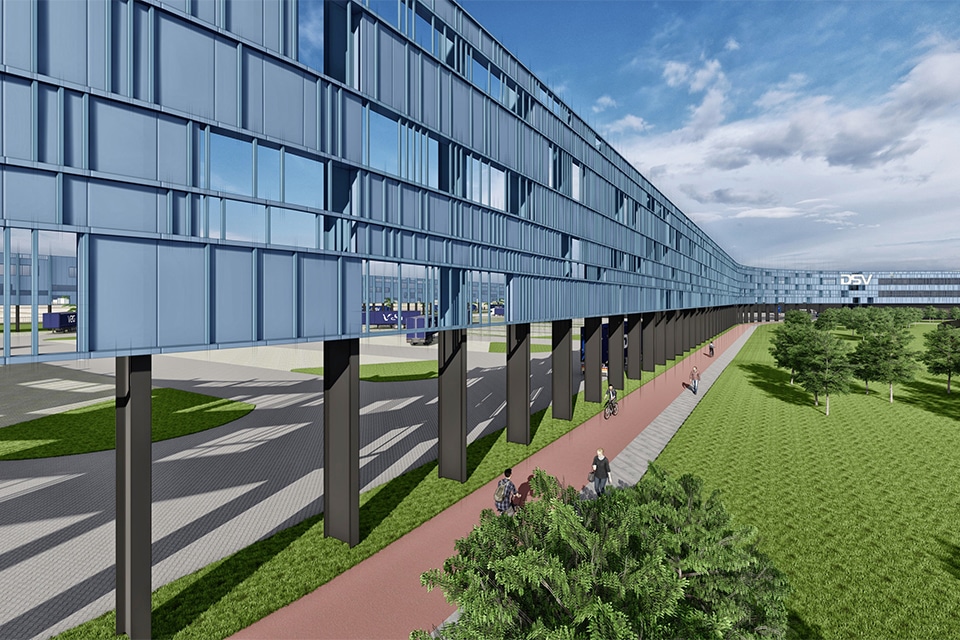

Hybrid construction of concrete and steel

Commissioned by Lidl Nederland, Bouwbedrijf Vrolijk is responsible for the construction work and installation techniques, except for the refrigeration systems. "We checked the design of FKG Architecten aan de Zaan and all the consultants and made an optimization in the piling plan. Then in August 2020 the piling work started," Mosselman says. "Prior to construction, the plot was raised with a body of sand. Concrete piles were poured for the foundation, on top of which 346 concrete columns, 1,200 m2 of wide slab floors, 1,800 m2 of hollow-core slab floors, 1,790 m2 of structural walls, 2,945 m2 of insulated walls and 14,752 m2 of fire walls were installed, among other things. On top of the concrete structure, a steel roof structure with steel roof panels was installed." The cladding is also made of steel, giving the new building an industrial look, he says. "At the docks, we are installing over 200 dock doors with dock levellers."

Conscious, sustainable and lean

To meet the high BREEAM-NL ambition, a predetermined percentage of recycled ('Chain of Custody') concrete was used in the shell, Mosselman said. "In addition, we use 'green' steel (NEN-EN-ISO 14001) and FSC-certified wood. The origin of these materials can be proven by us. Moreover, the project is registered with Bewuste Bouwers, which formulates concrete principles for environmental management, corporate social responsibility, safety and sustainability on and around the construction site." Because of the large size and tight schedule, Bouwbedrijf Vrolijk has opted for a lean project approach. Weekly coordination meetings are also held with ancillary and subcontractors, which keeps the speed of the project. The new building should be completed by the end of this year.

The distribution center in Almere is the second distribution center that Bouwbedrijf Vrolijk is building for Lidl. Earlier, a DC with 38,500 m2 of office and industrial space was completed for Lidl Germany in Moerdijk.

Construction Info

Client

Lidl Netherlands

Architect

FKG Architects at the Zaan

Contractor

Construction company Vrolijk

Steel Construction

Hofman Steel Construction

Concrete elements

Preco

Cooling and heat pump installation

Voets & Donkers