A planning puzzle

In total, no less than 100,000 m2 of floors are involved, which will be installed in phases. "Planning-wise, quite a puzzle," says Jeroen Boers of Twintec Netherlands.

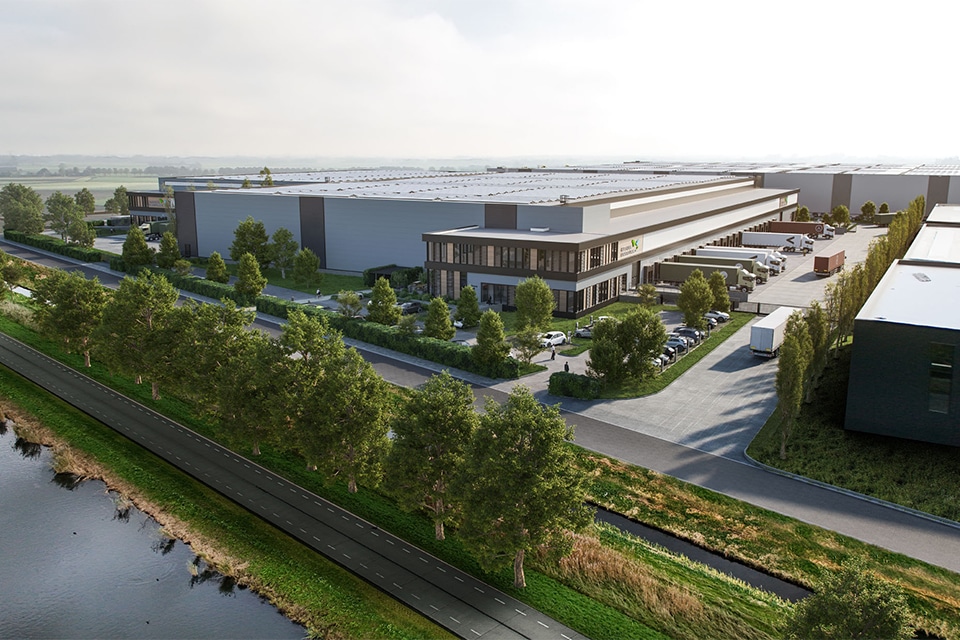

Twintec is familiar with Lidl distribution centers. "As a group, we operate globally. For example, we also recently had the opportunity to create the floors in new distribution centers of the supermarket giant in Germany and Ireland," continued Boers. "Our scope for the distribution center in Almere involves realizing 60,000 m2 of warehouse floors, 30,000 m2 of loading pits and the outdoor area and 10,000 m2 of pressure layers. Since the warehouse will soon be largely equipped with refrigeration and freezer cells, unlike a conventional warehouse, a lot of technology will be integrated. Installers like to have quick access to the warehouse to start certain activities. For us, that means we can't plan and execute the work contiguously. It's broken up into all kinds of sub-areas, and that makes it quite challenging from a planning perspective at times."

Currently, Twintec is in the process of implementation. "It is exclusively about traditionally reinforced floors, without high requirements in terms of flatness. So no higher mathematics. Nevertheless, here too we are striving for optimal end quality. According to schedule, we will deliver the final phase around the construction vacation."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Twintec.

Contact opnemen

Contact opnemen