Ancient craftsmanship reigns supreme

All automation and state-of-the-art superflat machines notwithstanding, the floor in Rensa Family's new and durable distribution center was applied and finished entirely by hand by Twintec. Time-honored craftsmanship reigns supreme. And that has absolutely no consequences for flatness, it turns out. On the contrary. An interview with Marieke Pitlo of Twintec Nederland about the 'top sport' delivered.

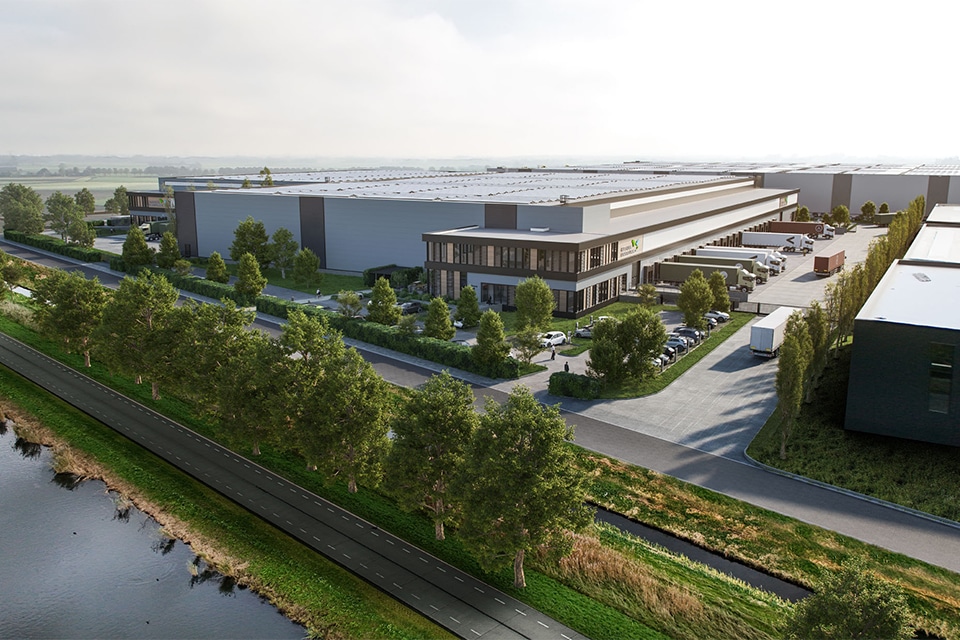

In Doetinchem, the sustainable distribution center of Rensa Family, wholesaler of heating and ventilation products for the Dutch market, was completed late last year. "Everything at the wholesaler revolves around CO2-reduction, so are storage and logistics," Pitlo knows. "Reason enough to build the 15-meter-high warehouse as sustainably as possible. The building has no gas connection, but has solar panels, heat pumps, underfloor heating and LED lighting. The materials have also been carefully chosen to reduce CO2-emissions as low as possible. That also explains the choice of our Twintec Ultimate floor, delivered according to our total concept Design, Build and Guarantee."

Twintec Ultimate provides both direct and indirect savings in CO2 emissions.

Twintec Ultimate

In Twintec Ultimate, the global leader in steel-fiber reinforced concrete floors combines traditional reinforcement with steel fibers. "By using steel fibers in the concrete, less traditional reinforcement is needed and the floor can be made thinner. This results in both direct and indirect savings in CO2-emissions, from less use of concrete mortar and steel to fewer transport movements," Pitlo explains. "By planning all the execution phases in tight succession, we were able to make optimal use of our employees' craftsmanship. Preferring manual labor to the use of super-flat machines means less CO2-emissions. Incidentally, the use of machines on this project was quite difficult anyway, due to the floor heating present. Nevertheless, even without these machines and by hand, our people realized an optimal floor for Rensa that meets the required flatness requirements, in this case NEN 2747 class 2. The flatness is even close to class 1, according to measurements that we always hand over to the client according to our total concept Design, Build and Guarantee."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Twintec.

Contact opnemen

Contact opnemen