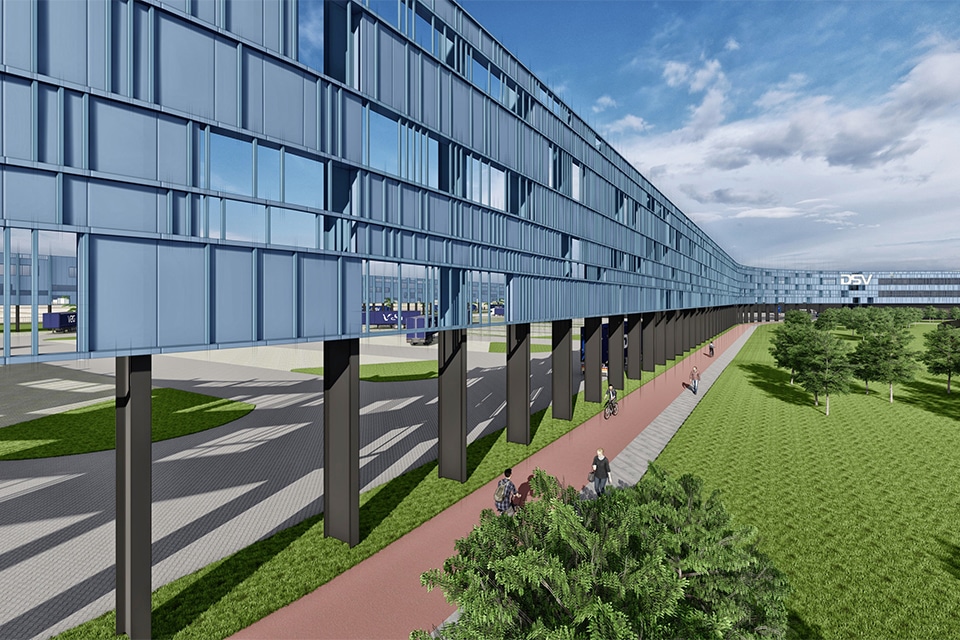

Impressive concrete for DSV Moerdijk

Prefabricated with precision

How do you keep the momentum going in a construction project of more than 240,000 square meters? By engineering all precast concrete elements - from walls to floors and specials - cleverly, producing them yourself and getting them on site at lightning speed. Preco demonstrates this at DSV's new distribution center in Moerdijk.

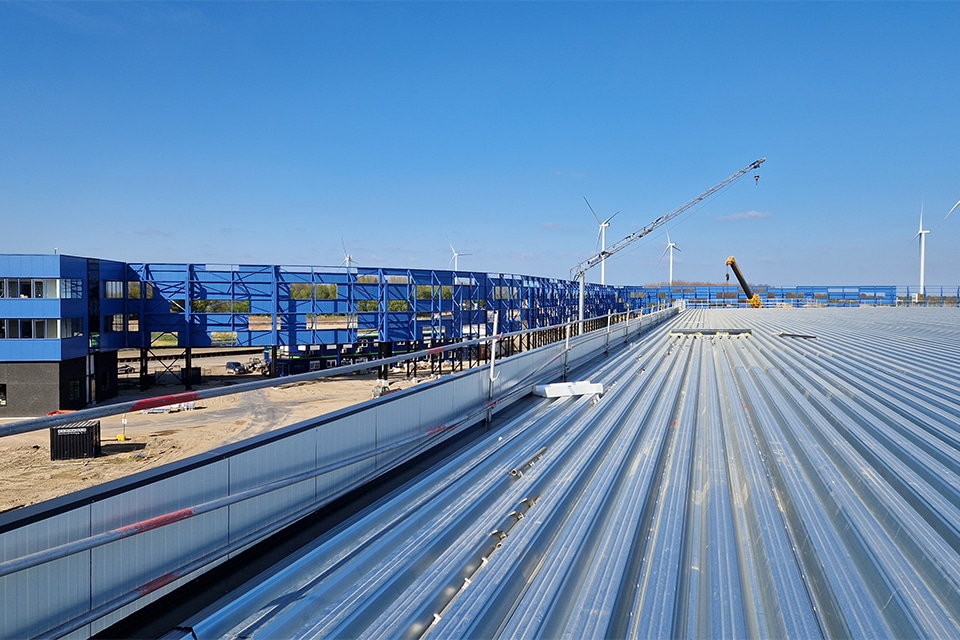

From the start, Preco was intensively involved: from engineering to producing and partially assembling the precast concrete elements. "We translate the client's technical requirements into our production standards and coordinate the planning with the assembly crew. Everything under one roof: that makes us unique in the Netherlands," says head of project management Stefan Jongewaard. For this mega project, Preco supplied, among other things, 85,000 m² of hollow-core slabs and 27,000 m² of walls such as fire walls, elevator core walls and insulated facade panels. Extra special: For one section, Preco assembled the entire concrete structure with columns, beams, hollow-core slabs and walls, including beams weighing 50 tons each.

Non-stop concrete logistics

To keep the pace of work high, Preco and Construction Company Vrolijk worked with a smart transportation system. Says Jongewaard, "We set up a hub on the construction site so that trailers could be swapped 24/7. This allowed assembly to continue without interruption." During the peak period, five assembly crews were working simultaneously.

Building scale and acuity together

The strength of this project is not only in the concrete, but in the cooperation. By constantly tuning in and keeping each other on their toes, all partners managed to keep the logistics in perfect sync with construction. "We really found each other in pace and precision," says Jongewaard.