Runways up to 27 meters wide super-flat in one pass

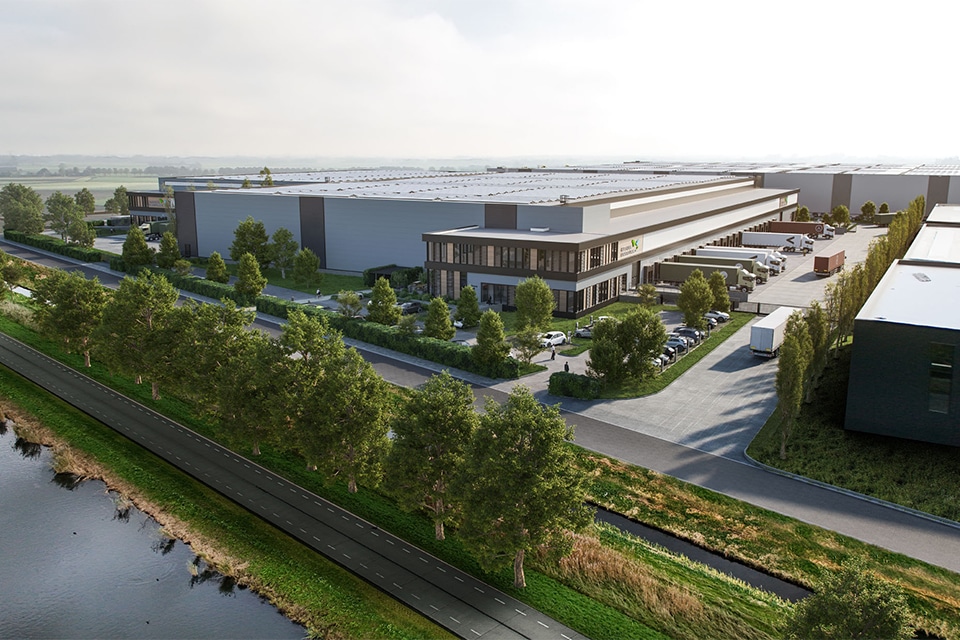

Distribution centers are getting bigger and bigger and the same seems to be true for the column-free spans of these buildings. Loos Betonvloeren responds to this with its brand new Giga Screed; an impressive machine that can super-flat a strip of up to 27 meters wide in one go. The machine was recently officially put into use in Den Hoorn, near Delft, where Loos Betonvloeren helped build a distribution center of 50,000 m² gross floor surface for contractor Goldbeck.

"With this machine we can lay a super-flat floor of over 2,000 m² in one day," says Dirk Loos, general manager of the concrete flooring specialist from Obdam. "And speed means saving costs, although it's all about quality in the first place, of course."

Faster, cheaper, flatter

"The first thing about the Giga Screed is that we can make lanes up to 27 meters wide with it. A unique feature in concrete flooring country and, as far as I know, the largest size in Europe. Thanks to the Giga Screed, we can not only build faster for clients, but also save costs. Architects can also draw in approximately 29 meters of column-free space and more usable floor area." In distribution centers, flatness requirements are becoming increasingly stringent, Loos knows. "This is due to automated storage and picking systems and forklifts that have to operate higher and higher racking. Our newest addition can handle all that without any problems."

Technical gadgets

The Giga Screed is essentially a huge roller that flattens freshly poured concrete. "Only the machine builder has incorporated every possible technical gadget," Loos emphasizes. "The system is modular, allowing for different widths, up to a maximum of 27 meters. There are also built-in LED spots for good lighting of the workplace and the machine has a high-pressure sprayer on board. This allows us to clean the machine and related tools at all times. Furthermore, there are so-called movers on the heads with which the Giga Screed can be moved independently on the work site. Foreman Dennis Schoenmaker, who sits here on the buckboard, has been involved from the beginning in the development of this machine, which was designed entirely from the workplace." The entire machine is also completely wirelessly controllable.

Shrink-free, no joints

Before the Giga Screed can get to work, pre-pouring strips are laid on both sides of the columns using hand rollers. These pre-cast strips are lined with steel angle lines and form the driving lanes for the machine. The reinforcement runs under the angle lines. Says Loos, "We can basically create infinitely large areas with our floor systems that are shrinkage-free and joint-free." Once the reinforcement is in place and the Giga Screed is ready, the pouring can begin. With a concrete pump and concrete trucks driving back and forth, it's lightning fast: once several meters of concrete have been poured across the entire width, the machine goes over it several times and (super)flat is the floor. Finally, the monolith finishers finish it off.

Engineering in accordance with the strictest standards

Loos Betonvloeren does more than just pouring concrete floors. The pile foundation, the substrate into which the rubble is incorporated, the floor thickness, the composition of the concrete and the reinforcement; everything about such a floor must be right in order to get the most efficient solution for the customer in terms of floor load, flatness, construction speed and cost. "In order to achieve this in the best possible way, we like to keep control of the process," said Loos. "That is why we are also happy to take care of the engineering of these floors, in accordance with NEN 2747 Class I and DIN 15185. In addition, of course, we still provide the other floor designs, including NEN2747 Class 2 to 7, wall torts, et cetera, for all branches of construction. From utility to infra and everything around it. With six pouring teams and about thirty monolith finishers, every day we do what we do best: with love for concrete, making the Netherlands a little bit more beautiful every time."