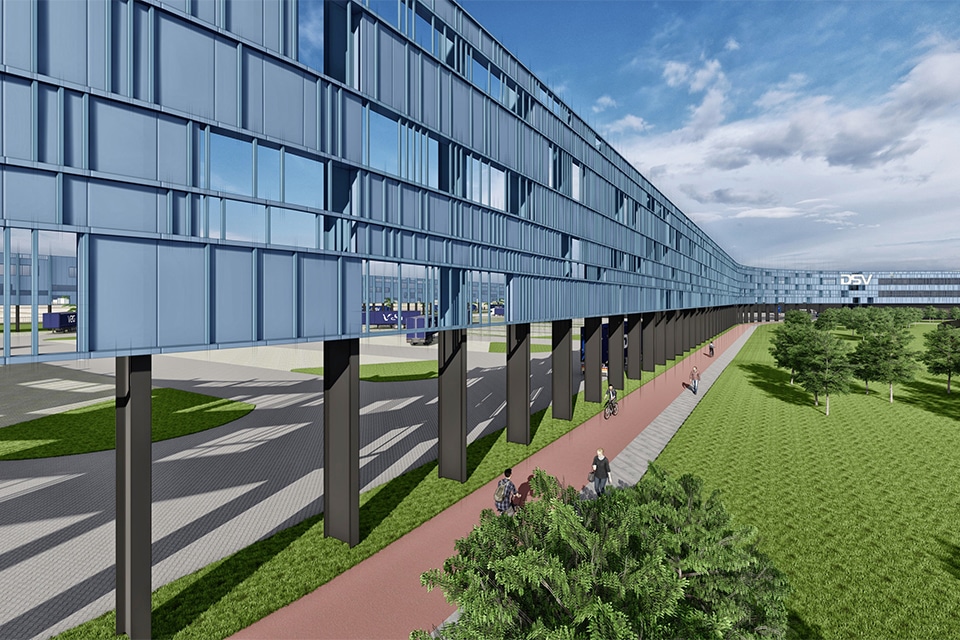

NH3/CO2 cascade system keeps DC Lidl at an ideal temperature

High-quality insulation, approximately 7,000 solar panels, LED lighting, rainwater recovery and sophisticated cold and heat production contribute to CO2-neutral operations and a BREEAM-NL 'Outstanding' qualification. The refrigeration system with air-to-air heat pump function will be developed, manufactured and installed by Voets & Donkers Koeltechniek en Luchtbehandeling on behalf of Lidl Nederland.

With the cooling and heat pump installation, Voets & Donkers is, among other things, building on the cooling installation for the Lidl distribution center in Oosterhout, which was put into operation in February 2019. "With a cooling capacity of approximately 6,000 kW, the installation in Almere is slightly larger," says Peter Donkers, general manager of Voets & Donkers. "Moreover, Lidl in Almere can rely on an even more modern, even more advanced and even more energy-efficient design, with state-of-the-art technology. The system operates on the basis of the natural refrigerants ammonia (NH3) and carbon dioxide (CO2) and is cascaded so that the cooling continues to run at all times. An additional cold water circuit is also attached to the system, allowing even more energy-efficient cooling."

Constant temperature and humidity

Among other things, the refrigeration plant takes care of freezing the eutectic plates (cooling elements), which are used for refrigerated transport to Lidl stores in North Holland, Flevoland and part of Utrecht. "In addition, the installation keeps all freezer and refrigeration cells at a constant temperature," Donkers said. "Think for example of the cold stores for meat, dairy, vegetables, fruit and chocolate, where specific temperatures (-30 to +20°C) and humidity requirements apply. The installation therefore also integrates a possibility for humidification." The residual heat from the chiller is efficiently used to heat the offices and other DC areas. "In the winter months, when less cooling is required and the residual heat supply is insufficient, the heat pump function is automatically activated. This enables the plant to still produce sufficient heat."

All disciplines under one roof

A major difference with the project in Oosterhout is that Voets & Donkers first assembled the complete engine room in its factory in Schijndel. Then the installation was disassembled again, coated and transported to the construction site in modules, Donkers says. "A conscious choice, because it allowed us to install much faster. Moreover, we have all the equipment, materials and expertise at our fingertips in Schijndel. Our organization has more than fifty professionals in a variety of disciplines. From engineers to electricians, welders and fitters. This enables us to engineer and produce fully in-house compressor skids, air handling units, switch panels and other installations tailored to the customer's needs."

10 years of management, service and maintenance

The new building should be completed by the end of 2021. Then VND Technical Services' refrigeration specialists will be in charge of managing the installation for 10 years. "In order to remotely monitor the complete cooling and heat pump installation, an extensive control system is provided," Donkers said. "We continuously receive data on temperatures, pressures, running times, power consumption, et cetera, based on which we can provide customized maintenance and service and guarantee an optimal installation condition for a long time."