The beauty of boldness:

Next to the headquarters of Trespa International B.V. in Weert, an architectural masterpiece called Nemho (Next material house), the brand new shared R&D center in Weert, has been showing off since mid-2020.

"Nemho fulfills a dual purpose. It is a technology and competence center for all companies belonging to the Broadview Group, but at the same time it contributes significantly to the presentation of our products and know-how. The building itself and its spaces symbolize the company's ambitions and our quest for excellence," explained André Horbach, CEO of Trespa. Pieter Peters, leader of the expertise center, adds, "Our goal was to create an environment that is attractive to top engineers and scientific talent. In the field of high-tech, there are quite a few renowned companies located in our region. That is precisely why it was so important to provide an appealing and pleasant working environment; a place that inspires a sense of pride."

'We wanted to maintain the atmosphere of a campus, with maximum transparency and a spacious, open feel'

Architecture with a message

It is clear that Nemho is the result of high ambitions: the multidisciplinary and multinational team leads the development of advanced, sustainable new products within Broadview Holding. The group consists of five companies - Arpa, Westag-Getalit, Formica, Homapal and Trespa, has a global network of subsidiaries and is a global player in its core business: laminates and derived products. Peters: "Originally, we envisioned a kind of campus idea. For practical reasons, we later opted for one building. However, we wanted to retain the atmosphere of a campus, with maximum transparency and a spatial, open appearance. The exuberant use of natural light and the uncluttered interior design are intended to promote interaction and exchange. In addition, we are providing the R&D team with new, modern equipment and tools." Horbach further explains, "The architectural concept had to make our focus on innovation clear at a glance. To make an innovative statement, we naturally wanted to work with a top Dutch architectural firm. There were three firms on our shortlist, but Broekbakema from Rotterdam surprised us with a concept that was truly unique. An excellent working relationship grew with director Erik van Eck and we are more than satisfied with the result. When I recently visited the new R&D center with my fellow directors of the other group companies, we unanimously agreed: the building is simply an impressive success."

A completely new take on ventilated facades

Van Eck emphasizes, "I had never worked with Trespa® products before, but was convinced from the start that we had to come up with something really special - a spectacular idea that would express the untapped aesthetic potential of Trespa® Meteon® facade panels."

"We always try to develop concepts that inspire people and create buildings that make people happy to live or work in. That's why we like to communicate well with our clients. We favor an intimate collaboration where everyone is part of the design process. At the same time, our "natural" approach lent itself to incorporating some - albeit unusual - components: a pattern that bears resemblance to a snakeskin and a design inspired by a forest scene. It is a conscious reference to the material's origins, as Trespa® panels for 70% are made of natural fibers." He clarifies, "For many Dutch people, Trespa® panels are a fairly conventional option. So it was a challenge for me to completely surprise. Moreover, developing a new, progressive idea would fit seamlessly with the building's R&D goal. That resulted in us using Trespa® Meteon® panels that look and act like reptile scales."

A unique approach to facade design

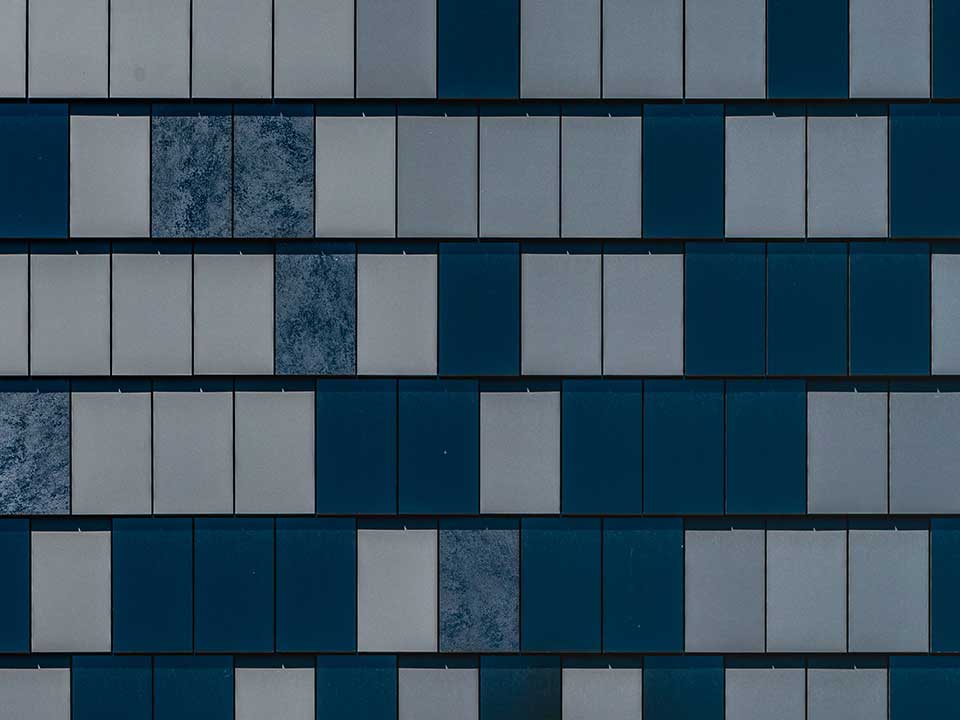

The idea assumed unusually small, overlapping panels that create a distinctive tile-like scaly pattern. Depending on the viewer's distance from the building, it always looks strikingly different: smooth from afar, but up close it reveals its staggered structure. For good measure, the architects added two additional visual layers. They combined different finishes and came up with a design where each Meteon® scale looks something like a pixel on a computer screen.

A technical tour de force

Even the most ambitious concept stands or falls on its execution. Both Trespa and Erik van Eck were well aware of this. "Because Nemho is the epitome of Trespa's expertise and the aesthetic possibilities of Meteon® panels, we 150% had to be sure that the end result would meet everyone's expectations," Van Eck explains. After Trespa described its ambitions and preferred method of collaboration, several contractors were given the opportunity to present themselves. The final choice fell on BAM Bouw en Techniek - Maastricht Region. Henk Janssen, senior project manager at BAM Bouw en Techniek - Maastricht Region: "In this project we worked in a construction team, in which BAM was involved from step one in an open dialogue with the client and the architect. As a construction contractor, we translated the architect's soul and ideas into feasible details and solutions. In doing so, respect for the design always remains the basis."

BAM involved a number of specialized companies in its work, including Limeparts-Drooghmans. Together with this Belgian facade specialist, BAM realized the detailing and one-to-one mock-up of the facade. Not only to optimize the detailing and engineering, but also to demonstrate the functionality and technical feasibility of the construction. This proved very convincing. The dimensional stability and requirements regarding the maximum tolerances of the Trespa® facade and the timber frame rear construction were worked out by BAM together with its structural engineer. Sven Drooghmans of Limeparts-Drooghmans: "The facade of Nemho was indeed a big challenge, but I tend to say that anything is possible. And that in the end it is still cheaper than flying to the moon. The mock-up was a turning point. From then on, things began to roll quickly. There is hardly a day when I don't have a Trespa project under my belt, so this work just had to succeed."

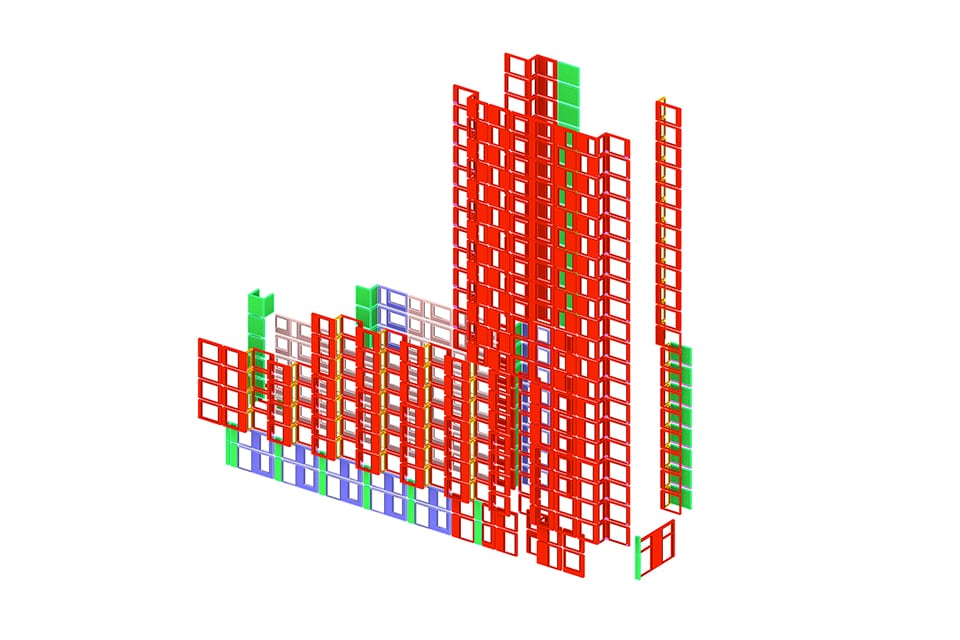

Limeparts-Drooghmans developed a custom solution to attach the small Trespa® Meteon® panels to the facade. In fact, the panels were each individually numbered to faithfully reproduce Broekbakema's design. Drooghmans continues: "The crucial component is a custom-made mounting frame. It is based on horizontal aluminum profiles with special hooks and adjustable screws. We also had to use perforated expansion profiles and ensure that the fastening systems for the panels remained invisible, in accordance with Van Eck's wishes. Although something like this has never been done before, it worked out well."

A construction site - almost - like any other

Because the construction was essentially experimental, there were many specific aspects to it that had to be carefully considered. As a result, the installation was very labor intensive. Gerard Karelse of Heinen+Partners of Barendrecht, near Rotterdam, was the safety officer and site manager of the Nemho project. At the same time, he was responsible for quality control. Karelse: "Installing Trespa® panels as roof tiles or slates is certainly very original, but you have to be sure that the cladding stays in place. This is in contrast to conventional, ventilated cladding where everything has already been tried and tested. By the way, the shingle attachment also has a small drawback: if a "scale" at the bottom or in the middle gets damaged, you have to peel off the entire column above that one sheet to replace it properly. Preventing this was part of my duties."

'The finished facade is of great beauty'

Many efforts, a rich reward

"In the end, it was well worth the effort," Karelse adds. "The finished facade is of great beauty. I thought it was extremely cool to be part of such an ambitious and successful project." Drooghmans explains, "Trespa®'s product range has evolved rapidly over the last ten years. I was able to follow it well, as we have installed some 80,000 m² of Trespa® panels and facade boards over the years. In terms of quality, Trespa is an "A" supplier. This is important because we mainly realize high-end projects for particularly demanding clients, and I hate to have to worry about that. Lately, Trespa has been very innovative and that is paying off: there is a wide range of attractive decors, vibrant colors and sophisticated finishes available."

"This cladding is unlike anything we have seen so far. The facades look fascinating to say the least, but at the same time the effects are very subtle. Depending on the time of day and whether it is cloudy or sunny, the varying shades of black of the Meteon® panels create all sorts of different hues and levels of shine. This was one of our biggest projects of late and definitely the most challenging. And for all parties involved, it is definitely a milestone."