2,778 precast concrete elements for High Five

A complete floor in four days thanks to clever prefab construction

On the Utrecht Science Park, construction is underway on High Five; a mixed-use project with 721 student studios and 200 student rooms spread over two residential towers of over 70 meters, with a 6-meter-high plinth underneath with catering, sports and resident facilities. Ambition of developer and contractor VORM 2050 is to build this project 20% cheaper and 50% faster. The smart and economic prefab construction of Stabiel Management makes an important contribution to this.

Stable Management is a regular consulting and fabrication partner of VORM 2050 and was involved in High Five as early as the tender phase. "Initially, the construction of High Five was to be entirely cast-in-place," explains Henri van Nistelrooy, technical advisor/project manager at Stable Management. "Because of the advantages of precast construction, however, we were asked to investigate alternative options. This resulted in a largely prefabricated shell with prefabricated elements, allowing VORM 2050 and building owner Stichting Studentenhuisvesting (SSH) to benefit from shorter construction time, higher construction quality, lower costs, less transportation, less nitrogen emissions, and a safer working environment."

Right tipping point

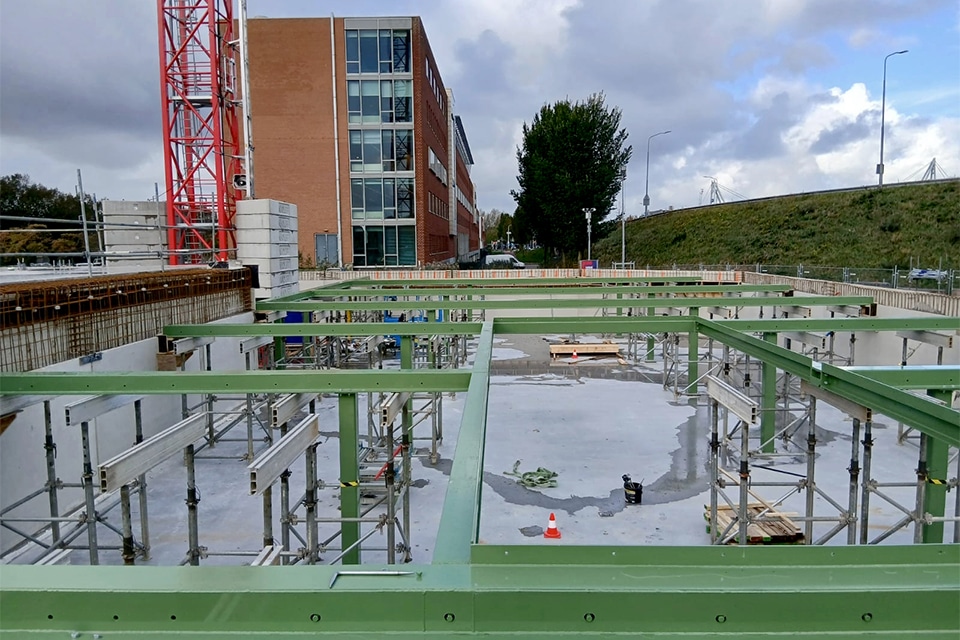

Below the second-story floor, the project is poured in situ, Van Nistelrooy explains. "A deliberate choice because of the special design of the substructure, where the columns are not directly under the walls. From the 2nd through 21st floors, however, the shell will be completely prefabricated with precast concrete elements and steel girders. This allows us to realize a complete building layer in four days. In the preparatory phase, together with chief structural engineer Pieters Bouwtechniek, we searched for the right turning point of construction methods. We also divided the construction into manageable elements that can be produced, transported, hoisted and assembled technically, economically and safely."

Smart and efficient

In addition to design and engineering, Stabiel Management is also responsible for the production and assembly of the precast shell, which consists of 1,088 precast concrete walls, 1,452 solid floor slabs, 132 concrete stairs and 106 steel beams, Van Nistelrooy says. "Following the construction, VORM 2050 has extended the precast concept to the finishing as well. For example, High Five also uses precast facade elements, precast bathrooms and precast installation skids. In the four days that we realize a floor, we also take the bathrooms and finishing materials up with us. This eliminates the need to transport these products via internal elevators. That, too, is smart and efficient construction, in our opinion."