Impressive car showroom

'Challenges make work fun'

Janssen Aannemers is building the brand new and impressive Porsche Centrum Brabant in Oisterwijk. A real prestige project. After all, it is the first Porsche garage in the new house style. "The shell achieved a BREEAM certification 'Excellent' in the design phase, which is quite special."

The building will be built in a U-shape and the exterior will be 100×100 meters in size. The showroom will have the distinctive Porsche facade. Project leader Ruud van Alphen of Janssen Aannemers: "The one leg of the U has three floors. This will house the Porsche showroom on two floors, the workshop, the warehouse and the office. The other leg will house the PGZ Showroom, a body repair shop, a car polish shop and a car wash. There will be a parking deck on both sides, equipped with a ramp."

New corporate identity

Porsche recently developed a new corporate identity (Porsche Corporate Identity) and it is being fully rolled out in this building for the first time. For the contractor, it means that Porsche's German parent company will regularly visit the construction site. "In addition, the shell has to meet BREEAM certification. That's pretty special and you have to do something for it. For example, the insulation values are higher than required by the Building Code. There are also sustainability requirements for the origin of the materials we use in the shell of the building. In addition, we have nine waste streams on the construction site. Of all the waste streams, at least 90% must be suitable for reuse. This is quite a challenge because we work with many subcontractors. So we pay close attention to this; we work on it every day. In addition, this is our first automotive project, so for us it is also the first time that we have had to deal with lift bridges and associated installations."

Six months of structural work, six months of completion

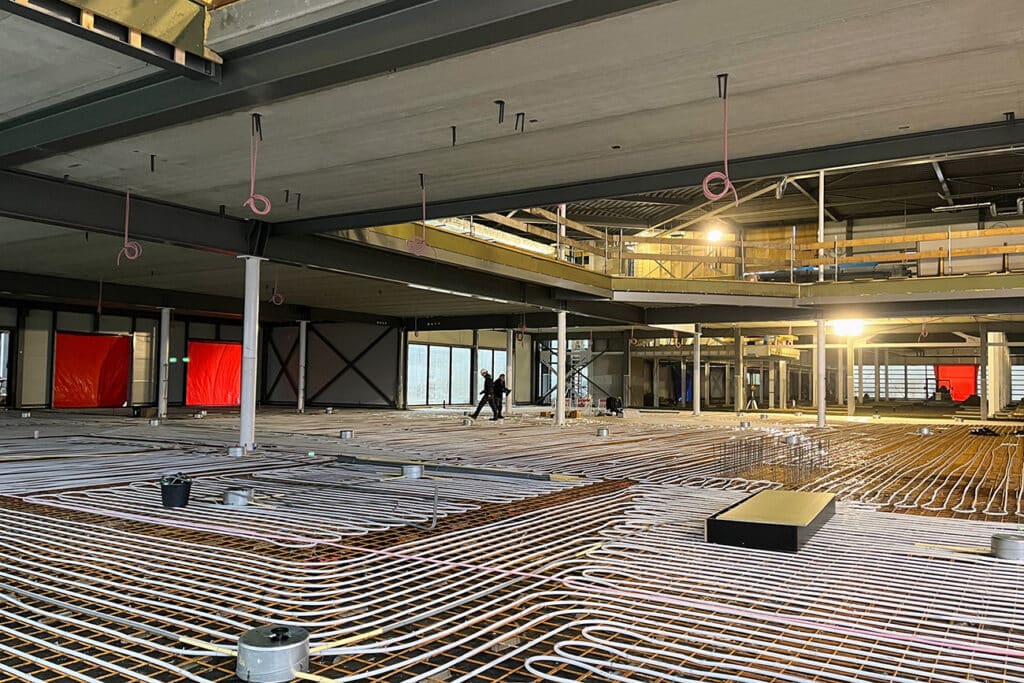

Meanwhile, the building has been wind and watertight for some time and the finishing work is in full swing. Six months of structural work will be followed by six months of completion time. Completion is scheduled for the third quarter of 2024. "Strict requirements also apply to the finishing. To supervise this, Porsche appointed its own project manager. He knows all the important points so that we can take them into account right from the execution stage. He is here weekly. That works very pleasantly."

Mortar screw piles instead of steel foundation

As with any construction project, the contractor did not escape the necessary struggles. Just before the start of construction, the groundwater was very high. Wells were not feasible because of contamination in the adjacent terrain. Van Alphen: "That was a puzzle, but we came up with a good solution: instead of a foundation on steel, we opted for foundations on mortar screw piles. Boring would have caused months of delay and even then the whole problem would not have been solved. We had to dig three-meter-deep pits in the workshop. In order to make them, we came up with a solution in the form of a steel box without a bottom. We poured floors into it and created a watertight box, which was then set in the ground. In order to set it correctly, we had to act very quickly. This was because this work took place below the groundwater level and so the hole could quickly fill up with water. This kind of challenge makes the work fun, especially when the solution is successful."

- Client VanE Beheer, Oisterwijk

- Main contractor Janssen Aannemers bv, Moergestel