New cold store for Maersk is sustainable, energy efficient and airtight

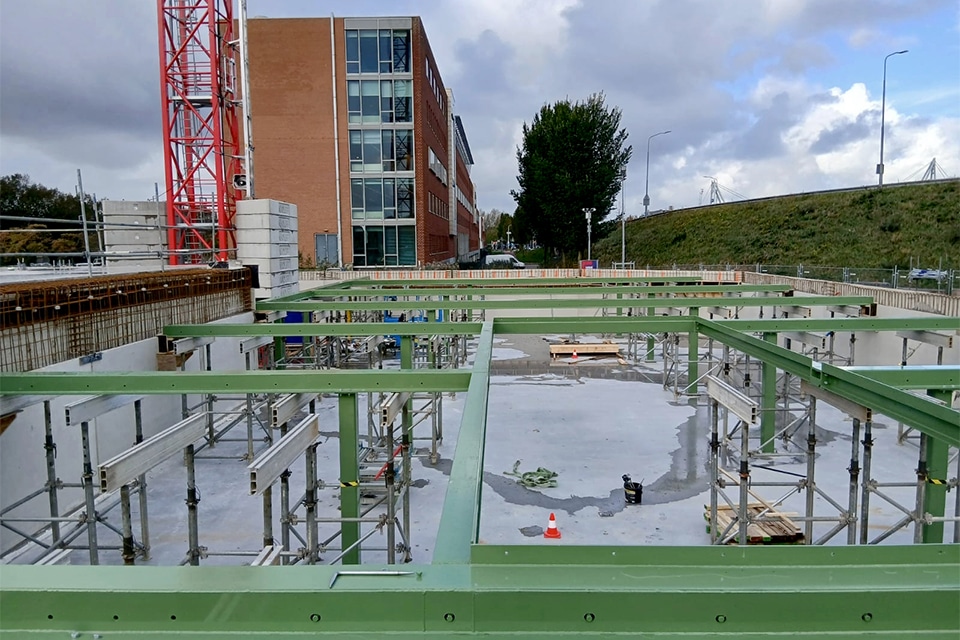

On the Maasvlakte in Rotterdam, a new cold-storage warehouse for the Danish logistics company Maersk is under construction. The ambition for the new building is the BREEAM 'Excellent' certificate. The design and construction are also fully in line with Maersk's zero-emission target by 2040. To take the energy performance of the new building to the highest level, explicit attention is being paid to sustainability, energy efficiency and airtightness. The materials, connections and detailing of the coldstore and the warehouse have been chosen to create an airtight box. The sandwich panels of Isocab by Kingspan make an important contribution to this, as well as to achieving specific fire standards..

"Building a cold store can only be done right once," emphasizes Andre Pes, Commercial Director Benelux at Isocab by Kingspan. "The highest technical standards must be the starting point from the outset. To support clients, architects and contractors in this, we like to be at the table as early as possible. For example, to recommend the most suitable panels based on the technical specifications, user requirements and local conditions. Once a cold store is completed and the refrigeration system is switched on, it remains operational until the building is taken down again. Post-insulation is very complex. So if you save on insulation values today, you will pay the price for that for 40 (!) years. A price that, due to the high (and uncertain) energy rates, is considerably

can add up."

Vaporproof separation

"Maersk's coldstore will soon be maintained at a constant temperature of about -25°C," Pes explains. "Because temperatures outside the walls of the coldstore can easily reach +35°C or more in summer, a strict and vapor-tight separation between indoor and outdoor climate is necessary. For example, to prevent temperature fluctuations, cold losses, frost and ice formation. Our sandwich panels with Quadcore insulating core contribute to this, with a lambda value that is more than 10% better than traditional PIR insulation panels." Sales Manager Wim Polfliet: "Whereas the BREEAM Rc value for cold storage buildings is set at a minimum of 10.5 m2K/W, our Quadcore panels achieve an Rc value of 12.5 m2K/W. The sandwich panels in this project - for exterior wall, roof, interior wall and ceiling - outperform the standard. This gives the end customer the flexibility to adjust interior temperatures in the future."

Of course, these achievements stand or fall with expert assembly, he emphasizes. "This is why we are very pleased with the cooperation with assembly partner K.I.M. Nederland B.V., to whom we supply our sandwich panels. Moreover, we help take care of the proofing. In case of construction modifications, our engineering department will gladly go back to work, so that Maersk can be sure that our panels meet all construction criteria."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Isocab by Kingspan.

Contact opnemen

Contact opnemen