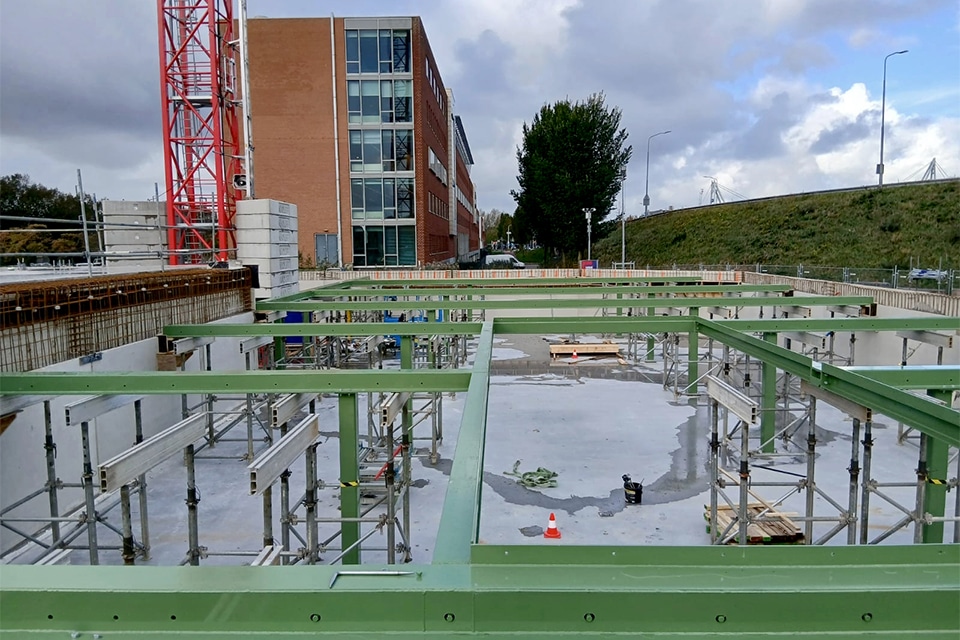

Prefabricated shell of unprecedented scale

‘Our biggest project ever’

The Blox is the largest precast project ever for Mombarg Beton. “The size, complexity and technical challenges are greater than anything we have completed before,” says a proud Ted Jansen of Mombarg Beton. “We are delivering the entire precast high-rise shell, consisting of columns, beams, walls, roof panels and various additional precast elements. A project in which our expertise, speed and cooperation are at their maximum.”

In total, Mombarg Beton processes 5,000 m3 of concrete and 600 tons of reinforcement in nearly 600 full loads of precast elements. “Everything is big, heavy and technically complex. Exactly where our strength lies,” says Jansen.

Lightning-fast production cycle

Production is tightly organized. “Per layer, we apply a lead time of only eight days, where we are always two cycles ahead of construction. This results in a planning period of about 16 days for VORM Bouw. In December 2024, we started engineering the precast shell, starting from the fourth floor. The first layers are cast in-situ, as are all the floors of the high-rise building by the way, creating a unique synergy between cast-in-place concrete and precast components.” A key component, then, is the coupling between the floor fields and precast walls. Heavy anchors and double bushings are used for this purpose. Solutions that Jansen says are not often seen, but are necessary to correctly transfer the force effect.

Engineering in three phases

The engineering was deliberately divided into three phases: the prefabricated shell of the third through thirteenth floors, the fourteenth through twenty-fifth floors, and the twenty-sixth through thirty-eighth floors. “This approach provides an overview, better coordination and a higher degree of manufacturability,” says Jansen. “Our partner Snijders Ingenieursgroep is taking care of the calculations for this. We take care of the drawing work. Since May 2025, we have been delivering 7 to 8 freights of precast elements every week - and for as many as 14 months, until the summer vacations of 2026.”

Big, heavy and durable

The precast parts are impressive. Walls up to 18 tons, with dimensions of 8.6 meters long, 3 meters high and 30 centimeters thick. “Where possible, we add concrete rubble aggregate and reduce the use of cement for a more sustainable concrete mix. We do this from an intrinsic motivation,” Jansen says. “The walls are solid with excellent reinforcement for optimal coupling to the floor fields. Above the door recesses, additional concrete is integrated to ensure force action.”

Designing together for the best result

According to Jansen, Mombarg Beton's strength lies in its early thinking along with the project. “From the offer stage, we worked with VORM Bouw and Snijders on design, detailing and manufacturability. No standard prices or separate deliveries, but a joint process in which we develop the best prefab solutions. This is how prefab really comes into its own. Not because it has to, but because it is the best solution.”