Regulations in the facade finishing industry

Building top quality together

The facade finishing industry is brimming with craftsmanship and innovation. With an extensive system of regulations and certifications - such as those of KOMO - companies are actively committed to ensuring the highest quality standards. This shows how serious the sector is about quality. Marc Veenstra, director-owner of IBS Afbouw, sees opportunities for further growth together: “The rules are there for a good purpose - to guarantee quality. If we strengthen enforcement and involve suppliers more on the shop floor, we can reach an even higher level as an industry.”

KOMO offers three valuable certificates: for mortar coating and decorative plaster, for mineral facade strips and for stone strips. Each certificate represents significant quality assurance and costs several thousand euros.

“It's a great way to underline your professionalism,” says Veenstra. “Although in practice it is not always actively asked for yet - unlike VCA certification, for example - it does offer an opportunity to distinguish yourself professionally.”

IMPROVE AND STRENGTHEN

Veenstra sees room for further professionalization. “Hired personnel require extra attention. As a sector we can take steps in this by offering clear explanations and guidance. Especially since a large part of the work in this industry is performed by migrant workers, this way we prevent long-term problems and further strengthen the industry's image together.”

SAMPLING AS QUALITY ASSURANCE

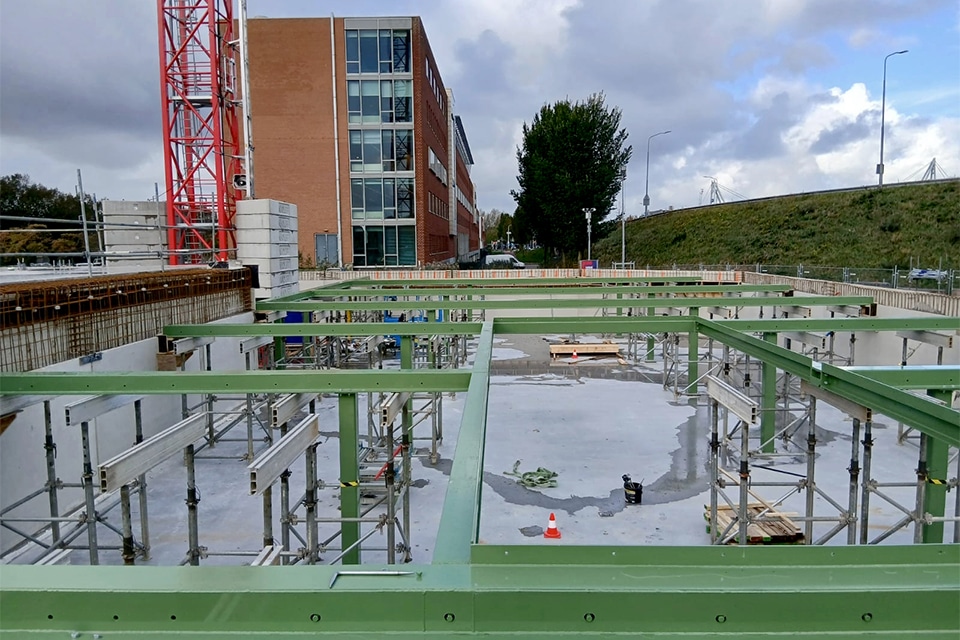

On the construction site, Afbouw Gevelupport carries out random checks on behalf of KOMO. These checks are designed to ensure that work is carried out according to the correct working methods and under the correct conditions.

Companies indicate in advance where they operate and what resources they deploy, which ensures transparency. Veenstra sees room for improvement by, for example, also testing for the presence of qualified personnel. Veenstra: “We ourselves always work with the extensive 90-page rulebook with the applicable guidelines. We actively share that with our employees and hired workers, which ensures that everyone is well informed.”

SUPPLIERS AS PARTNERS IN QUALITY

According to Veenstra, suppliers can play a valuable role in ensuring quality on the construction site. “With Sto, my regular supplier, I always get expert advice and support, that cooperation really makes a difference and contributes to the success of a project.”

He advocates a more proactive attitude: “Let suppliers think along and check that their products are being applied correctly. After all, if a project does not go well, that also affects their reputation.” Veenstra sees possibilities in a strengthened supervision model: “Additional quality employees who actively go into the country and can make adjustments if necessary.”.

EXPERTISE AS STRENGTH

At IBS Afbouw, quality comes first. Thanks to years of experience and close cooperation with Afbouw Gevelupport, each project is expertly executed. “A good product is important and correct application is crucial,” Veenstra emphasizes.

“We choose expertise and customization through involvement from the beginning. This is how we prevent damage and repair work. An eight is not enough - we aim for an eleven. This is how we raise the industry to a higher level and guarantee sustainable quality.”.