Serial housing construction can be faster, more sustainable, and more cost-efficient

Online configuration tool for prefab concrete shells

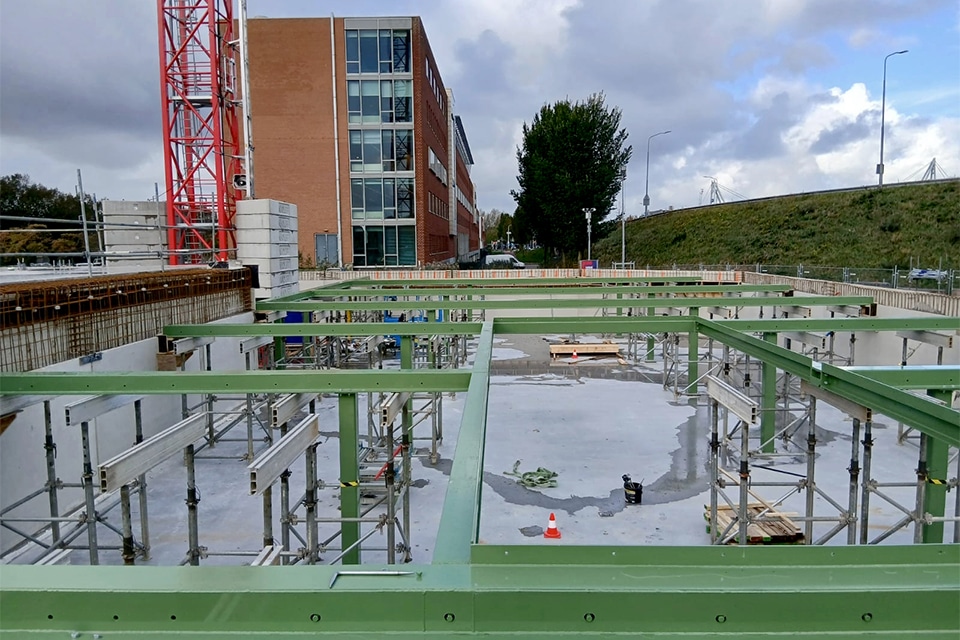

The construction challenge in the Netherlands remains urgent: hundreds of thousands of homes need to be built, and in a short period of time. Prefab concrete shells are increasingly seen as the key to accelerating this process. They combine robustness and sustainability with a more predictable construction process. MBS Group is responding to this with GeoFrame, a digital platform that supports the entire process—from configuration to quotation and integration.

GeoFrame is an online configuration tool (SaaS) that allows contractors and developers to assemble prefab concrete shells based on predefined housing types. The platform contains fourteen basic models, including terraced houses, corner houses, and semi-detached houses, which, thanks to different widths and depths, yield 56 configurations. Options such as flooring, extensions, insulation, and window frames are available for each type. Within minutes, GeoFrame generates a 3D view, a shareable link, and a price indication. Architects and contractors can also make their own additions, ranging from facade finishes and brickwork to layouts and buyer options. This creates a complete model that can be used immediately for design, permitting, and construction.

Standardization with flexibility

“One of the major advantages is the time saved by developers and contractors in the preparation and permitting processes,” says Victor Woesthuis, marketing manager at MBS Group. “Where a traditional quote can sometimes take four to six weeks, GeoFrame delivers a conclusive calculation within a few days. Through the normal process, the process of prefabricated shells is often fragmented and time-consuming. Small design variations lead to additional engineering work, while contractors and developers need speed and predictability. GeoFrame therefore combines standardization with flexibility. The result: fewer errors, shorter lead times, and more control over costs.

In addition, GeoFrame links the configuration to BAG data, immediately generating a visual plot of the homes to be built. This saves a lot of time when applying for and assessing permits.”

Simplicity

The configurator contains fourteen predefined housing types with different widths and depths. “This allows for more than 56 configurations,” says Woesthuis. “You simply choose the type of home, the dimensions, and options such as floor type, extensions, insulation, and window frames. GeoFrame then automatically generates a 3D model, a shareable link, and a price estimate. We have been testing the software with various customers since 2023, and functionalities were added for the reintroduction in early 2025. During pilots with medium-sized contractors, the system proved to save up to 20% time in the preparation phase. Users also indicated that the predictability in costs and planning was a decisive advantage in tenders.

For example, in a serial housing project in the east of the Netherlands, sixty homes were prepared in record time using GeoFrame.”

MPG and MKI scores

Woesthuis sees the advantages of GeoFrame alongside those of prefab concrete. “We know that prefab concrete requires less labor on the construction site, has a shorter construction time, delivers high structural quality, and has a longer service life than cast-in-place shells. GeoFrame uses standardized components that are smarter in design and result in less material waste. GeoFrame also contributes to sustainability through the use of recycled insulation and cast window frames for better airtightness. The MPG and MKI scores per shell are immediately visible in the configurator. How easy do you want it to be?”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met MBS Group.

Contact opnemen

Contact opnemen