The laboratory of the future is in veghel

Modern facilities and plenty of room to grow

At business park the Amert in Veghel, the professionals of Bouwbedrijf van de Ven have built a new and sustainable laboratory with office space for NutriControl. Thanks to the three-story new building, not only has NutriControl's capacity doubled, but its range of services has also expanded. For example, the new facility is equipped with state-of-the-art testing instruments for food safety and nutritional analysis. Both design and construction focused on future-proofing, with smart technology and room for staff and building expansion.

The ball for this new building started rolling as early as June 2021, when Bouwbedrijf van de Ven was invited to submit an offer for the structural work. “Some time later, the mechanical and electrical installations were added to this,” says Ad van der Linden, project manager at the Veghel-based construction company. “In Hoppenbrouwers and Van Eck Elektro we found the right partners for this. Working in a construction team, we translated the aesthetic design by architectural firm LIAG into a final design and execution design, on the basis of which we started our construction work in February 2024. Last June, the new building was completed exactly according to our schedule.”

Clip-in frames

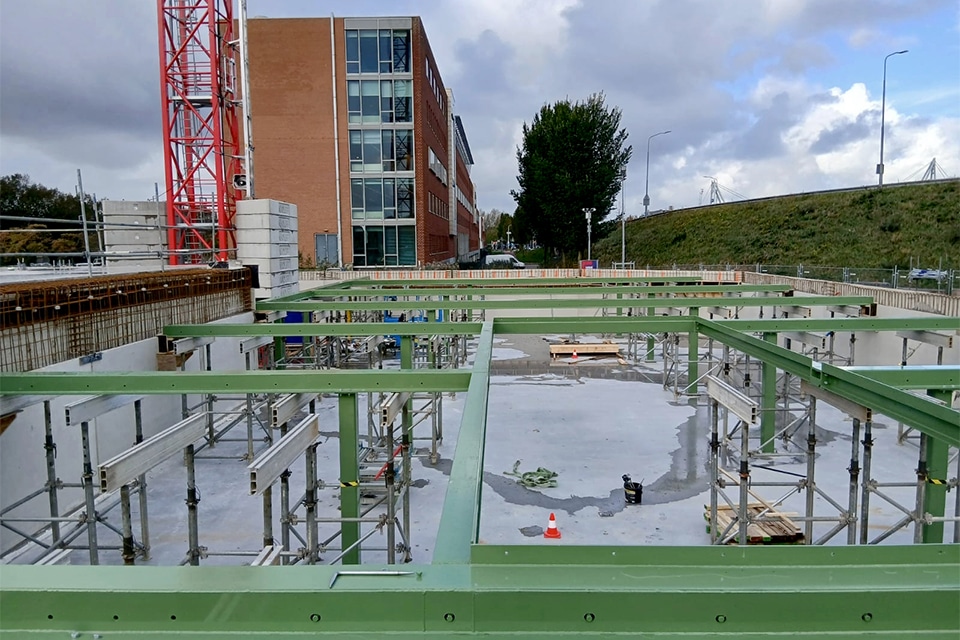

The new laboratory building for NutriControl has an area of about 5,400 m2, divided into three floors and a technical area on the roof. “At the basis of the new building are a steel structure and hollow-core slabs,” says Van der Linden. “The facade is constructed of sandwich panels and clip-in frames. A special system, which brought several advantages. For example, no structural frames were required in this project. Moreover, the frame openings could be cut out just-in-time. We first closed the facades and poured the floors, and then on the fair-weather days all the frame openings were made and the frames were pulled in.” The first floor has a curtain wall on three sides. “As facade finishes, gold-colored composite awnings and fins in various slants were chosen, which play with the sun at any time.”

Beautiful interplay

According to Van der Linden, it was a challenge to match all the facade components perfectly. But also to properly align architectural and installation components. “There are a huge number of installations in this building,” he says. “Fortunately, our installation partners already had experience with installations in laboratories, but even so, little space was left for the structural issues and fire protection provisions. We held BIM consultations every two weeks to gain insight into and properly resolve any clashes. A nice interplay of client, installers and structural contractor.”

High weights and wind loads

“On the roof of the new building is a considerable number of air handling units, whose air ducts are connected to each other and the building at a height of three meters. This required a specific substructure. For example, to be able to carry the high weights and wind loads correctly,” says Van der Linden. “This also required a lot of work. Because of advancing insights in the field of installation, the roof was closed as shortly as possible before completion.”