'Customization is our strength'

Steel sheet-concrete floors for transformation of monumental Van Gendthallen

With project Van Gendthallen, five monumental factory buildings in Amsterdam Center-East escape demolition. The listed factory buildings from the late 19th century are being prepared for the future in a sustainable manner. The buildings will have 7,500 m2 of solar panels and 12,500 m3 of recycled concrete. For air conditioning, a thermal storage system with wells at a depth of 160 meters has been realized, supplying heat and cold to the floors. Thanks to concrete core activation (BKA), very little additional energy is needed to heat or cool the various spaces. The BKA pipes are cast into the steel plate concrete floors from Tullingh & Partners, which form the new floors of the Van Gendthallen.

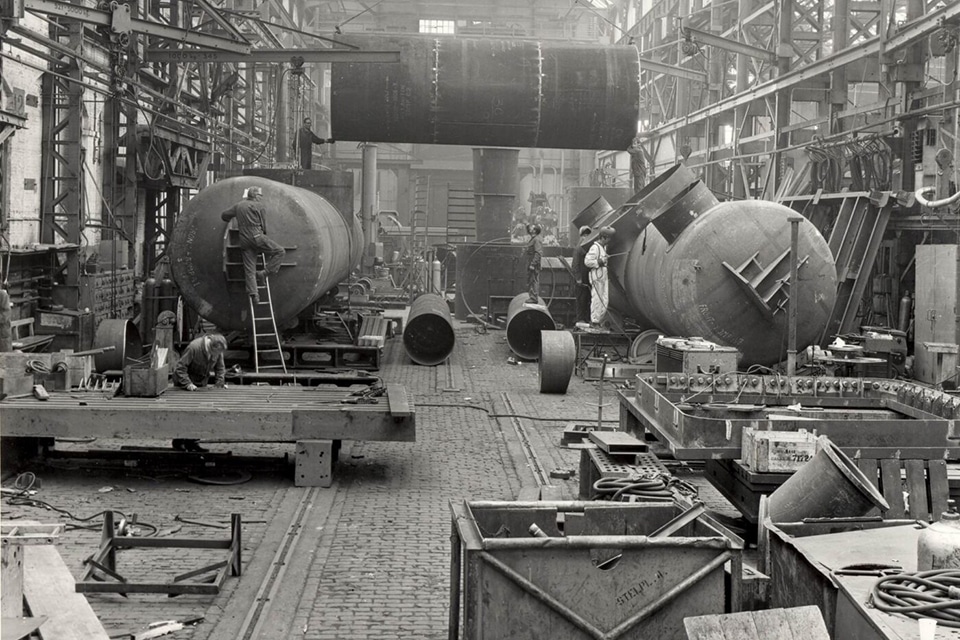

The Van Gendthallen was designed in 1898 by renowned Amsterdam architect Dolf van Gendt and built on behalf of the Royal Dutch Factory of Tools and Railway Equipment. Our country's first steam trains and diesel engines were built on the historic site. Since the end of the last century, however, the halls have been empty and fell into disrepair until a new owner came forward. On his initiative, the halls are now being given a new purpose as an epicenter for pioneers in technology, arts and design, without losing their industrial character. In addition to the Drift Museum, the halls will soon provide space for various restaurants, stores, businesses and flexible offices.

four-story floors realized.

Early involvement

The transformation is being carried out in a building team construction, with Van Gendthallen as the client and Vic Obdam Staalbouw as the steel construction company. Almost all buildings will have a new and in-situ poured first floor with concrete core activation on which the new steel structures will be mounted, says Charles van Oldenbarneveld of Tullingh & Partners. "The storey floors are executed with our uninsulated steel plate concrete floors, benefiting from significant weight savings, minimal concrete use, better structural connections and perfectly coordinated logistics and assembly. While some halls will have three storey floors, the highest hall will even have four storey floors. The highest steel plate-concrete floor is at no less than 13.5 meters high! We were involved in the construction team at a very early stage by Vic Obdam Staalbouw to optimize the design for this."

Custom (implementation) design

"The existing steel structures in the monumental halls could not be used. That is why Vic Obdam realized new steel structures," said Van Oldenbarneveld. "Within the module dimensions of this steel structure, we had to engineer one floor system with one cross-section of 24.5 cm, which would be usable in all applications. Both for spans of 3, 5 and 8 meters. A challenge, but that is precisely where our passion and strength lie. The Schedule of Requirements for the Van Gendthallen specified a minimum allowable load of 3.7 kN/m2 and a maximum allowable load of 5.5 kN/m2. The floors also had to incorporate the pipes for underfloor heating and cooling. A finish with black concrete on top and steel plates in an anthracite color on the bottom was also requested. Our design meets the requirements seamlessly."

Emission-free to the right places

In March 2024, Tullingh & Partners began assembly, working in a construction train behind Vic Obdam Steel Construction. "Before we start our work, safety nets are installed in the buildings," says Van Oldenbarneveld. "Because internal transport of the profiled steel plates is no longer possible in this case, the steel plate packages are already placed in the right places during the construction of the steel structure. All the steel plates are transported just-in-time to the construction site, where they are moved to the right places using electric forklifts, electric aerial platforms and electric cranes."

Good cooperation

Tullingh & Partners is responsible for the engineering, delivery and assembly of the profiled steel plates. "Subsequently, Van Gendthallen applied the reinforcement, mounted the floor heating pipes and poured the concrete in-house. To properly coordinate these processes, good cooperation is essential. That's where this project really shines. The atmosphere on the shop floor is enormously motivating and everyone puts their best foot forward. This absolutely benefits the quality of this special project. Everyone takes care of the best ingredients, creating a building that we can later enjoy together and to the fullest. As Tullingh & Partners, we are super proud to contribute to this project."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Tullingh & Partners BV.

Contact opnemen

Contact opnemen