Conditioned rooms for A.F.L. Barendrecht

Especially for A.F.L. Barendrecht, Inoflex supplies and assembles twenty cold rooms and two freezer cells, including door systems. A.F.L. Barendrecht specializes in cold storage, refrigerated transport and container transport of vegetables, fruit, packaged consumer products and non-food goods. A well-conditioned space within its new building in Ridderkerk is therefore of great importance.

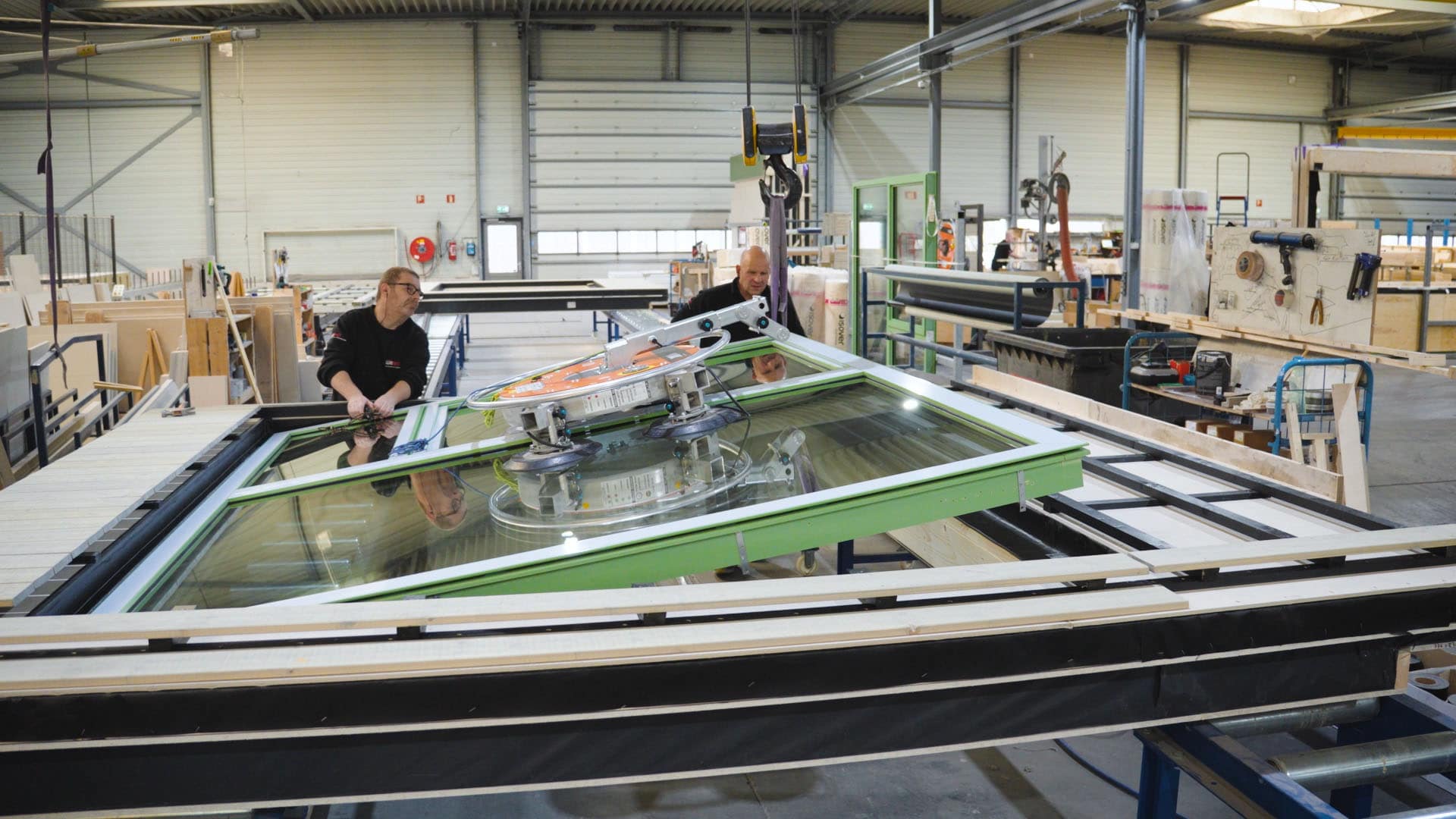

The new building, scheduled for completion in mid-2024, consists of a distribution center with refrigerated and freezer cells, a refrigerated shipping area, a repacking area and offices. Commissioned by Hercuton

Inoflex there more than 15,000 m2 of panels. The intention is for the building to receive a BREEAM 'Excellent' certificate. High demands are therefore placed on the conditioned rooms and way of working, says Gregor Massop, sales manager and technical advisor at Inoflex. "The panels have a high insulation value and we meet the requirements in terms of waste flows. We have a partnership with a company that recycles the panels. The steel plate of the panels is shredded, the foam is pulverized and the propellants are even taken out. It is made into new steel, PIR panels and the propellant is reused to produce sandwich panels."

The CradleCore sandwich panels will be taken back by Inoflex in 30 years, allowing the building to implement new sustainability measures. "The technology is so new that there are no panels in circulation at this time that have been recycled or shredded. They will be by then. This way, the building remains as sustainable as possible," Massop said.