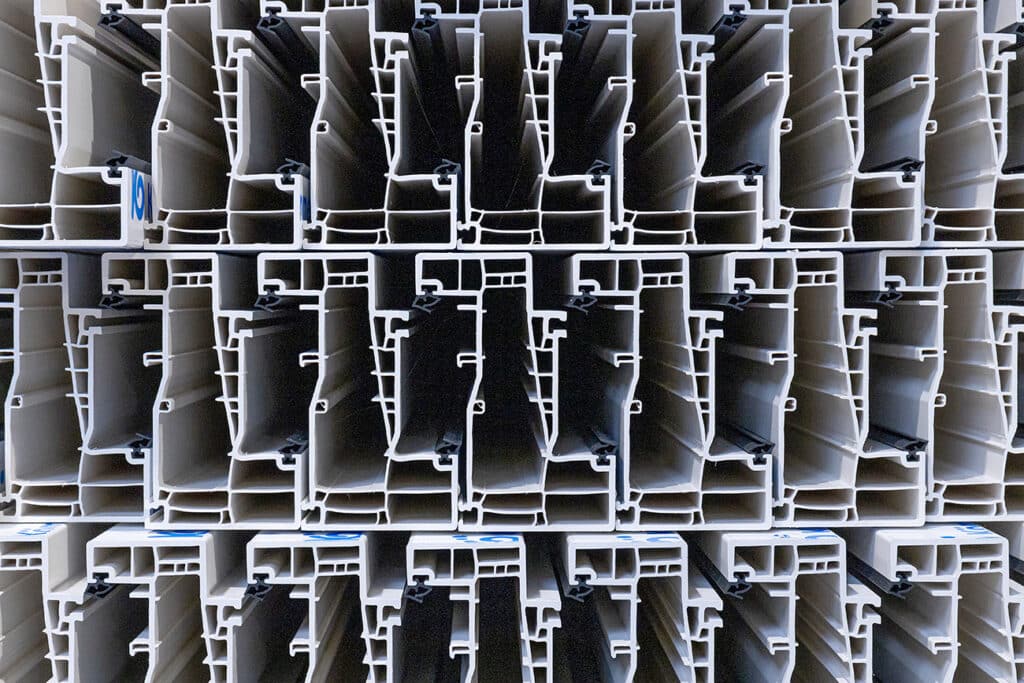

Tomorrow's plastic window frame contains fossil-free PVC

Chain partners have first with window frames made of bio-attributed PVC

No sustainability without innovation and no innovation without sustainability. That's the way Kömmerling has been going for years, looking for solutions for the window frame industry that contribute to a better world of tomorrow. In the ongoing search for further sustainability, Kömmerling has reached a new milestone: the company now produces window frame profiles with bio-attributed PVC. Together with partner Kumij (frame manufacturer) and BAM Wonen, there is a wonderful first to report. BAM has used plastic window frames and doors with bio-attributed PVC in a sustainability project in Steenwijk. A bold step, taken with confidence, as Kömmerling has a solid track record of sustainable innovations.

What is Bio-Attributed PVC?

We speak with Jelmer Bijlsma, manager of sustainability and innovation at Kömmerling Netherlands and Jan Slagman, commercial director of Europrovyl and driver of innovation and sustainability within VHZ, a group of companies that includes Kumij, Europrovyl, Transcarbo, Smits Kozijnen, Alwood and Kozijn Service Nederland. He is therefore closely involved in the application of the new bio-attributed PVC profiles. Bijlsma explains what bio-attributed PVC is: "In bio-attributed PVC, some of the raw materials of the plastic material are replaced by a renewable alternative. In this case it is biological residual material from sustainable forestry and agriculture. The result: fossil-free PVC. This makes the window frame profiles much more durable and less environmentally damaging, while maintaining quality. Bio-attributed PVC window frames are just as strong and stable as the traditional version. Bio-attributed PVC already has some applications inside and outside the construction industry, however, we have the first for application in the plastic window frame industry."

Minimizing environmental impact together

"Within the FTZ Group there is a common goal to minimize our environmental impact. The desire to use more renewable raw materials is a direct result of this," Slagman says. "It starts with material recycling and ends with recycling." Research shows that raw materials have the greatest impact on environmental impact. So by focusing on renewability at the front of the chain, you make the biggest gains." Bijlsma adds: "From the wood pulp that comes as residual material from sustainable forestry and agriculture, vegetable oil, 'tall oil,' is extracted that can be converted to Bio-Naphtha. Traditionally, to make a polymer compound for PVC, ethylene is used from Naphtha, a fossil fuel. By replacing this fossil Naphtha with Bio-Naphtha, a completely bio-based ethylene can be obtained, which is used for our bio-attributed PVC. The proportion of this in our feedstock is as much as 43%."

Certified from A to Z

The process of making window frame profiles from bio-attributed PVC began back in 2019, right when this innovation was announced worldwide. Bijlsma: "In terms of product development, applying bio-attributed PVC is not that drastic. Much more important is to understand and control the process. All process steps must be transparent and independently certified, just like the logistics and administrative operations involved. We came full circle at the beginning of this year in our production in Germany and now the profiles made of bio-attributed PVC leave the factory fully certified." Slagman adds, "The bio-attributed PVC is 'fossil-free', but it still contains mineral raw materials. The LCA (Life Cycle Analysis) proves that the environmental impact of this is low. It has a much more favorable environmental score than other systems. Nevertheless, we continue to strive for further sustainability and the LCAs are a perfect basis for this."

This is certainly not an end point

For Kömmerling, the application of bio-attributed PVC is not an end point in the quest for improvement. "On the contrary," says Bijlsma. "It is a new starting point. This quest never ends; we also see it as a shared responsibility of the chain." Slagman continues: "That requires transparency in sharing data and brings with it the responsibility to constantly encourage each other. This development stands alongside other developments. For example, Kömmerling now produces profiles with a core of recycled material. We can now apply the shell of bio-attributed PVC to these. That currently provides the most sustainable solution you can think of."

Innovating on sustainability is intrinsically woven within both Kömmerling and FTA. Anyone looking at the history of these market leaders will see that sustainability was already a spearhead when it was not yet on the agenda elsewhere. "It's not just nice that it can be done, it just has to be done," Bijlsma says fervently. "To indicate the role sustainability plays within our ranks, you only have to look at our staff. People are specifically assigned to it."

To innovate is to dare

Tall trees catch a lot of wind, as the saying goes. If you want to be a leader in sustainable innovations, you have to have guts. "This goes many times beyond optimization," Bijlsma explains. "If you are at the front end of development, then you just set a revolution in motion. That the market eventually follows is something we welcome. We're not doing it for our ego, but for a better world. Kömmerling has always been at the forefront of making plastic safer, cleaner and more sustainable. Bio-attributed PVC should therefore no longer be compared to the PVC of the past." For Slagman, there is no question that it is no longer just about making money: "To be relevant for the future, you have to move now. We want to take leadership in that, by no longer following. We want to be the accelerator, an 'enabler' for the industry."

Kumij took the bio-attributed PVC window frame to BAM Wonen itself, confident of finding a sympathetic ear there. But Kömmerling and BAM Wonen are no strangers to each other either, as evidenced by BAM's sustainability-related visit to the profile production in Germany. This completes the circle. Bijlsma concludes: "Like VHZ and Kömmerling, BAM Wonen has an enormous drive to build circularly, with a complete focus on sustainability. Its entire chain is transparent and this product fits in perfectly with that. Thus the confidence arose to renovate 19 homes in Steenwijk with bio-attributed PVC window frames. A bold step that we could take together as chain partners, because we know what we can gain from each other."

The introduction of bio-attributed PVC window frames marks an important milestone in the building and construction sector. It demonstrates the sustainable evolution of the sector and shows that innovation and environmental awareness are the way forward. With a concerted effort, a sustainable future is actually coming closer faster.