Why custom studs are becoming the standard in modern construction and installation

In the world of plant engineering and construction, precision is the key to success. Where previously standard lengths were the norm, we see a clear shift toward efficiency. Custom studs have become essential in this regard. Simply shortening long threaded rods on the construction site is no longer cost-effective.

For installers, fabricators and technical buyers is buy custom studs a smart investment. Whether for HVAC suspensions, complex steel construction or precast structures, using the right stud at the exact length saves time, money and frustration. In this article, we dive into the benefits of custom studs and why they are the smartest choice for any professional builder or installer.

Why standard threaded rods are not ideal for modern construction projects

Standard threaded rods of 1, 2 or 3 meters can be bought everywhere, but in practice they are often an obstacle to a streamlined process.

1. Lost time due to manual editing

Cutting threaded ends on site is time-consuming. For each cut, a fitter must saw, deburr, and repair the thread to make the nut operable. In a project with hundreds of fasteners, this loss runs into thousands of dollars in man-hours. Custom studs are delivered ready-made, including trimmed ends.

2. Risk of corrosion and weak connections.

When galvanized threaded rods are cut on site, a blank cutting edge is created that is extremely susceptible to rust. With professional custom wire rods, a seamless finish (such as electrolytic or hot-dip galvanizing) is ensured or high-quality stainless steel (A2 or A4) is used.

3. Material waste (cutting loss).

With standard lengths, you are always left with leftover pieces of 20 or 30 centimeters that are no longer usable. This cutting loss is pure capital destruction. With custom studs, you only pay for the meters you actually incorporate into the structure.

When do you choose custom studs?

Custom studs are indispensable in projects with precast concrete, tight installation spaces or high numbers of fastening points. They save processing time, prevent errors and improve project planning. Customization is also essential when dealing with varying lengths, tensile strength requirements or corrosion resistance.

HVAC and air handling

In technical rooms, space is often tight. Custom studs provide tight suspension of air ducts without protruding parts that can be dangerous for maintenance personnel.

View our range of threaded studs for HVAC

Steel structures and precast

When anchoring steel plates or connecting precast concrete elements, there is no room for error. Here, threaded rods with high tensile strength (quality 8.8 or 10.9) are often used, produced exactly according to the working drawing.

Order custom studs for steel construction

Installation technology in utilities

For cable trays and sprinkler systems, speed is crucial. Assembly crews can get straight to work with pre-sorted sets of threaded ends, significantly reducing the lead time of large projects. Discover custom fastener options

Why a technical wholesaler if XXLD threaded rod makes the difference

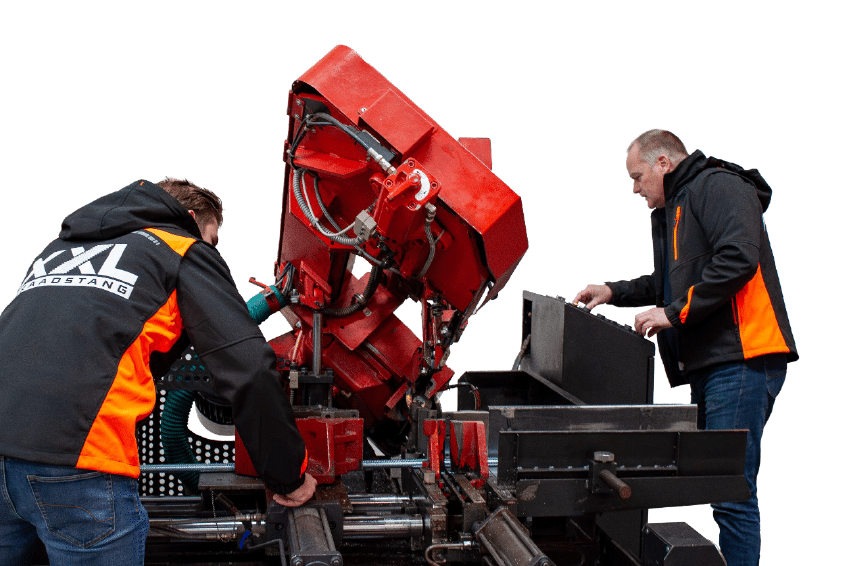

Outsourcing the sawing work to a specialist such as XXLDwire rod provides direct technical benefits:

- Extreme precision: Cut to the millimeter with professional machines.

- Ready to assemble: No burrs, nuts run smoothly directly on the threaded rod.

- Various qualities: Available in steel 4.8, 8.8, 10.9 and stainless steel (A2/A4).

- Logistics convenience: Delivered by floor or section bundled and labeled on site.

Conclusion

Custom studs are not just a product; they are a method of reducing failure costs. By moving preparation to XXLD threaded rod's workshop, you increase productivity on the shop floor.

Saving on your next project? Calculate your benefit and order your bespoke threaded ends directly at XXLDraadstang.co.uk.

FAQ: Frequently asked questions about custom studs

What is the difference between a threaded rod and a threaded rod?

A threaded rod is a piece of threaded rod cut to size. It is delivered in the desired length, ready for assembly.

What materials are custom wire ends available in?

We supply threaded ends in virtually all grades: from electrolytically galvanized steel 4.8 and 8.8 to corrosion-resistant stainless steel A2 and A4 (316).

How quickly can threaded studs be delivered to size?

Because we have our own cutting and manufacturing department, we can often deliver to the construction site within 24 to 72 hours.

Are custom studs suitable for HVAC and steel construction projects?

Sure. Our custom studs are widely used in HVAC installations, precast concrete construction and steel structures.

Why choose a technical wholesaler like XXLD Wire Rod?

Because we think along in customization, deliver quickly and comply with technical standards such as DIN 976 and ISO 898-1.

Also need custom studs?

Request a quote through XXLDraadstang.nl or call for direct advice. We deliver fast, accurate and project-oriented.