Steelwork carries wooden building in Haarlem

Acoustic decoupling and precision work in a hybrid residential tower

The first social housing tower to be built mostly in wood is under construction in Haarlem: Oostpoort Plot 1F. A sustainable project with a striking hybrid construction of CLT and concrete. For the steelwork in this special building, contractor HSB Bouw is working with MM Staal; a compact organization with broad expertise, says director Bart Melman. “We are a steel construction company without a huge team, but with broad specialization.”

MM Steel works on both new construction and renovation projects throughout the country. From load-bearing structures to stairs, fencing and stamping, the company has an all-round profile. Thanks to its own engineering, production and assembly, MM Staal delivers complete projects with short lines and clear coordination.

From basement to tenth floor

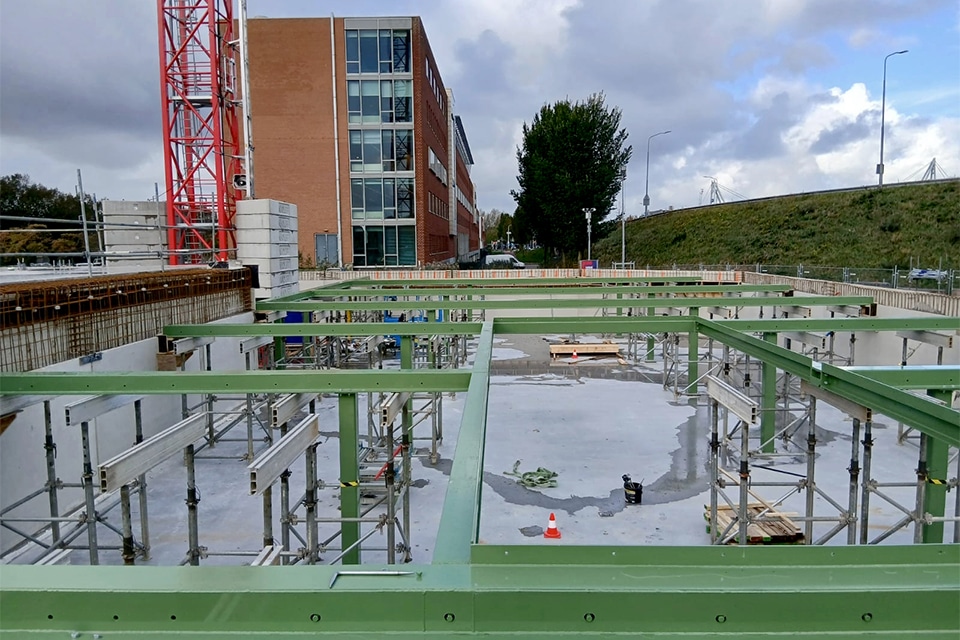

For Oostpoort Lot 1F, MM Staal was involved after a request for proposal. The job is extensive: the steelwork runs throughout the building. “We started in the basement, where we made the columns and beams for the basement deck. From there we continued to build the steel structure and then the balcony structures for floors one through ten.” Construction is proceeding on a tight phasing schedule. “We started in week 45 and a month later the steel structure was up to the third floor. From there we continue to build upwards. The expectation is that we will be finished next year.”

Acoustical challenges

The biggest technical challenge lies in the connection of steel to a wood support structure. “It's a building with a lot of wood - and wood is more acoustically sensitive than concrete. Therefore, our steel connections play a big role in reducing noise,” Melman explains. Decoupling is key. “The coupling between the UNP and our steel beams must be acoustically decoupled. We do this by separating the bolted connections with special rubber. This way we prevent sound from being transmitted through the steel.”

Looking Ahead

The technology is complex, but manageable. “If the drawing work is well prepared, it becomes standard work for us. The challenge is mainly in accurate placement and careful disconnection,” Melman says. The process is fully worked out in BIM. “An appropriate end result starts with good work preparation. Everything is drawn in 3D and welded in the factory exactly according to these models.” Cooperation with the construction partners is also excellent. “We are very satisfied with how the project is going, and I think that is mutual.” He concludes, “The scale and precision of this work really shows what we excel at as a company.”