Xella offers total care in challenging Groningen project with extreme design

Cellular concrete Hebel roof panels missing puzzle piece in unique roof design complex for youth housing De Woldring in Groningen

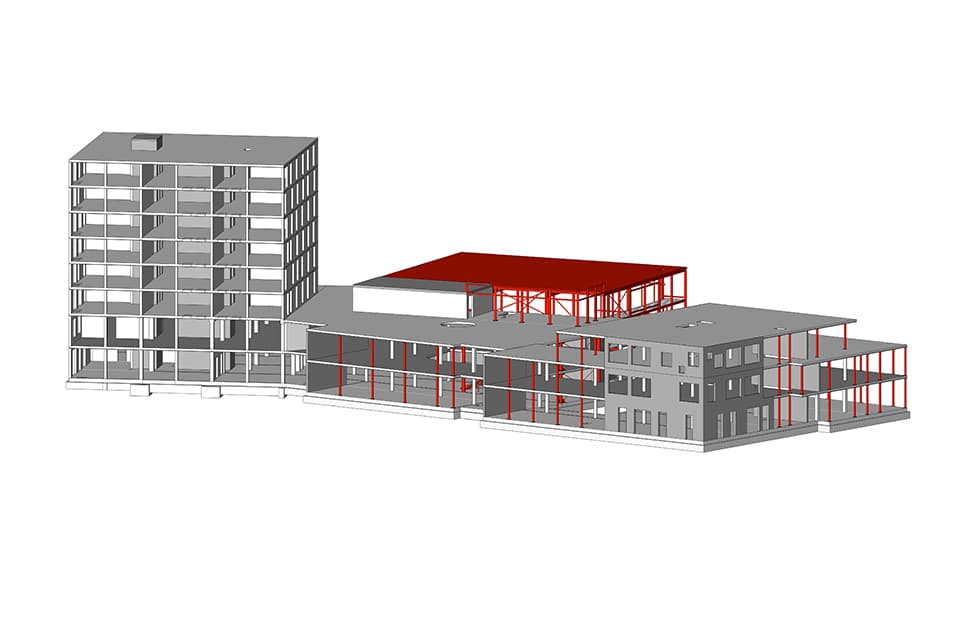

High-rise buildings usually cast quite a shadow in compact locations, but not in Groningen. There, Urban Climate Architects from Delft designed a unique building with ultra-sloped roof sections that follow the path of the sun. The result is maximum daylight ingress and sunlighting of the courtyard. The roof is built with Hebel roof panels from Xella, where the building physics and structural properties of aerated concrete are decisive. The ultimate freedom of form of the aerated concrete roof panels ensures that the desired roof shape could be realized.

Autumn 2019 saw the completion of De Woldring Locatie in Groningen, a new residential complex for young people with as many as 435 apartments. With 16 residential floors and 50 meters high, the building is a striking appearance on Groningen's Reitdiep. The building is colossal in size, but it is the architecture that catches the eye. And especially the design of the roof, which consists of six different building parts.

Inclination angle up to 45 degrees

The various roof sections support a steel structure with an angle of inclination ranging from 15 to 45 degrees. The design for the roof sections was initially drawn in wood frame construction, but gradually contractor Van Wijnen found out that wood frame construction could create building physics and structural problems. "Timber frame construction gave a chance of vapor accumulation under the roof, and due to the height of the building (50 meters), wind suction and wind pressure on the roof would be unacceptable," says Van Wijnen's work planner Zlatan Balalic. "We didn't want to take that risk, so we had to look for an alternative building material." Hebel aerated concrete roof panels turned out to be the missing piece of the puzzle. Balalic. "Due to the light weight of aerated concrete, minimal modifications to the underlying structure were required to stay within the confines of the design. At the same time, aerated concrete is moisture-regulating and the roof panels have a fire resistance of 120 minutes. In addition, aerated concrete increases acoustic comfort through sound absorption. This reduces the so-called effect of a hollow space. It also fits into our picture in terms of budget and aesthetics."

Design entirely in BIM

Xella handled the design, engineering and installation of the roof. "We drew all the roof panels and structural connections completely in 3D, after which our model was integrated into the contractor's BIM model," explains Xella's draftsman Michael Richardo. Especially challenging was the slope of the roof sections, i.e. that some roof surfaces have a slope in two directions, says Ricardo. "Especially since we had to take into account quite substantial wind and water load requirements."

Despite the structural challenges, the architect's design "always remained leading," Ricardo says. "To realize that, all the sheets were fully custom-made in Xella's factory. Each roof plate has a unique number." Once on the construction site, the "puzzle" of the roof can be put in place.

Close cooperation with abbotWassenaar

In the implementation phase, we worked with abtWassenaar of Haren. Klaas-Anne van der Heijden of the engineering firm was the point of contact for Xella. As chief structural engineer, he mapped out the impact of a different building material for the roof. "What does this mean for the foundation and the underlying steel structure? What is the best way to mount and anchor the roof panels? And what level of reinforcement of the aerated concrete is needed to handle the wind and water loads?" Constructive solutions to these were devised in close consultation with Xella. Especially the triple gradient in the different roof sections was a challenge for the assembly. "We first made separate 3D models for all the roof sections and their gradients. The solution was in the use of specially tailored valley beams and corner beams." 2

The roof panels were given maximum reinforcement to allow for possible water accumulation and wind loads (up to 5 kN/m2) to withstand. The Hebel cellular concrete was laid on top of the steel structure. To prevent the sloped roof panels from sliding off the steel structure, short, thick steel strips were welded on top of the steel sections every 7.2 meters. These strips provide resistance to the stacked weight. In places where the roof pitch equals the span of the roof slab, transverse strips are welded to the HE profiles. These hold the sheets in place. Finally, hook bolts are used to prevent the roof sheets from blowing up.

Unique design follows orbit of sun

The design of The Woldring Location is unique of its kind and for good reason, states architect Dennis Hauer of Urban Climate Architects of Delft. Because the building is in a very compact location, it has the lot in a grip, so to speak. "Sunlight from the courtyard and light (in the homes) were therefore major challenges," Hauer says. A lighting study offered a solution. Special software was used to map the daily course of sunlight relative to the complex, from all seasons. The results of the light study are reflected in the roof design and positioning of De Woldring Location. For example, the tallest tower is oriented toward the evening sun. But more far-reaching is the design of the roof and facade that ensures as much daylight entry as possible. Hauer: "The course of the sun has a fairly extreme curve, a kind of parabola. Based on the course of the sun, the roof shape was drawn as a kind of counter shape, so that all the houses take advantage of as much daylight as possible and the courtyard has daylight for as long as possible. It also produces a much more interesting building than usual. The sculpture is very much cut down. To make the design realizable, we tried to cut the roof into straight sections as much as possible." The result is six different roof sections, each with its own pitch. In addition, the different roof sections also have their own gradient.

The Woldring Location, a student and youth housing complex, is slated for completion in fall 2019.

Xella is the smart partner for building solutions in aerated concrete, sand-lime brick and mineral insulation boards. As the global market leader in its sector, Xella helps chain partners to build more sustainably, efficiently, qualitatively and simply. Xella does this by translating knowledge from the market and from building regulations into innovative products and concepts with comprehensive services. This product and service portfolio always offers partners a suitable answer to the questions and requirements of today and tomorrow.